Difference between revisions of "KRA"

| Line 5: | Line 5: | ||

|} | |} | ||

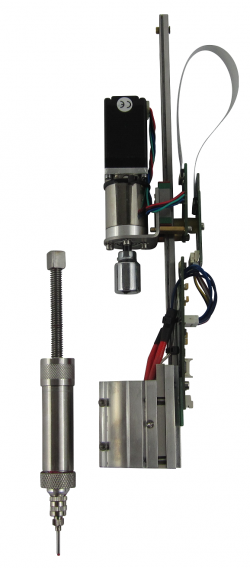

The KRA-15 is our 15cc print head for high viscosity emulsions which print at | The KRA-15 is our 15cc print head for high viscosity emulsions which print at 150°C (200°C upon special request). | ||

[[File:KRA-15.png|250px|left|KRA-15]] | [[File:KRA-15.png|250px|left|KRA-15]] | ||

Revision as of 21:40, 17 April 2018

The KRA-15 is our 15cc print head for high viscosity emulsions which print at 150°C (200°C upon special request).

This includes the following materials:

- Clays, including Metal Clays

- Pastes

- Emulsions

- Hot Glues, including 3M 3796

Additionally, the KRA can be used as an EMO or a VOL without heating the extruder.

Videos

- Overview of the head:

- Loading the head:

Loading the VCD Head (same as the VOL)

Loading the VCD Head (same as the VOL)

Description

- The KRA-15 has a 15cc stainless steel reservoir with a threaded collar at each end. The tube has to be loaded into the KRA apparatus before the bottom cap is attached. The top has a threaded rod, which is how material is displaced; the bottom holds a nozzle or luer adapter. Industry standard luer tips or needles are available from a variety of sources.

Loading the Head onto the Printer

As with all Hyrel heads, the following process should be followed:

- Start with a level bed and Repetrel running and connected to the printer.

- Load the gibs on the Head into the gib slots on the Yoke from above and slide the head down into place; the last mm of travel should be done gently, ensuring that the electrical connector seats properly (firmly and completely) into the receiving connector.

- Ensure the LEDs on the print head are flashing - this means the Head is communicating with the Motion Controller.

- Tighten the thumbscrew in the rear, to prevent the head from moving relative to the Yoke.

- If the Head doesn't show up in Repetrel, press and release the RESET button on the front of the printer.

- Once the Head is shown in repetrel, proceed to setting your Z-Zero position.

Loading material into the Head

Loading:

- Care should be taken to avoid air pockets, as this will introduce delay when starting and stopping material flow.

Unloading:

- Unloading is the same process as loading, only in reverse. Tubes and nozzles should be cleaned thoroughly after use.

Default Parameters

Default settings for the KRA are shown on the Cold_and_Warm_Flow page.

Adjustments

The only adjustments needed should be changes to the PRIME and UNPRIME settings, and will have to be dialed in based on how viscous and compressible your material is, and how narrow a nozzle or luer tip you are using.. In dialing in new settings, I usually double or half the settings for both STEPS and TIME, then make another print and reassess.

Firmware

Please see the Downloads page for the current firmware for your heads and your version of Repetrel.

Maintenance

While cleaning your print media from the tube and nozzle after every print is important, very little other maintenance is required on this head.