Cloning and Mixing

Cloning heads is when two heads will both execute the exact same gcode at the exact same time.

Mixing heads like the SMH-2 and DMH-2 each take the output from two other heads and blend them through static (SMH) or dynamic (DMH) blending baffles or blades, with final deposition of a (hopefully) homogeneous blend.

Whether you're mixing your output or not, step one is to clone the heads.

Cloning

Clone, slave, or parallel printing, is when one head makes a normal print, and another head makes the exact same print at the same time.

We will normally execute a T command first, to establish the primary or master head (generally the one to the left). Then the M703 command, cloning or slaving another head to the first.

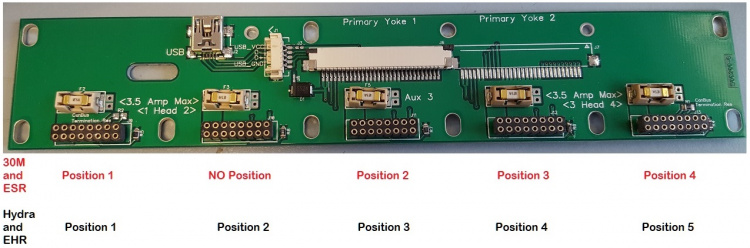

Remember, this is how we address the tool positions; note that the 30M and ESR have four positions, not five. Counting from the leftmost position:

| Command | 1st Slot | 2nd Slot | 3rd Slot | 4th Slot | 5th Slot |

|---|---|---|---|---|---|

| Tool Change | T0 | T1 | T2 | T3 | T4 |

| Clone Address | T11 | T12 | T13 | T14 | T15 |

| Master Address | S11 | S12 | S13 | S14 | S15 |

In the following example we have a five-position yoke; commands executed by the head in slot 1 (far left) will also be executed by the heads in both slot 3 (third from left) and slot 5 (fifth from left):

T0 M703 T13 S11 M703 T15 S11

These commands are decoded and executed by the printer as follows:

- T0 - Assign commands to Position 1 (the far left head on yoke 1)

- M703 - Begin to Duplicate Commands:

- T13 - Tool Position 3

- S11 - Slave to Position 1

- M703 - Begin to Duplicate Commands:

- T15 - Tool Position 5

- S11 - Slave to Position 1

Note that only Hydra (16A) and High Resolution Engine (EHR) units have five tool positions; other models have four only. See Understanding the T at the top of the Gcode page for tool position nomenclature.

Mixing

Now that you have the cloning set up, it's time to do the mixing. Connect the pneumatic tubing to direct the flow from the two supply heads to the mixing head.

The Static Mixing Head is easy - connect and you're done.

The Dynamic Mixing Head requires air pressure (to spin the blades) and an electrical connection (wires provided) to the primary head, to activate the flow valves for printing and non-printing moves. It also takes a command to control blade spinning speed.

Remember, this is how we address the tool positions; note that the 30M and ESR have four positions, not five. Counting from the leftmost position:

| Command | 1st Slot | 2nd Slot | 3rd Slot | 4th Slot | 5th Slot |

|---|---|---|---|---|---|

| Variable | T11 | T12 | T13 | T14 | T15 |

In the following example we will dispense 25% of the material from slot 2 and 75% of the material from slot 4:

M221 S0.25 T12 M221 S0.75 T14

These commands are decoded and executed by the printer as follows:

- M221 - Update flow calculations

- S0.25 - Material Feed Rate Multiplier 0.25

- T12 - On yoke 1, slot 2

- M221 - Update flow calculations

- S0.75 - Material Feed Rate Multiplier 0.75

- T14 - On yoke 1, slot 4

At any point, we can change the ratios - in this example, we'll change the ratios to 80% slot 2, 20% slot 1:

M221 S0.80 T12 M221 S0.20 T14

These commands are decoded and executed by the printer as follows:

- M221 - Update flow calculations

- S0.80 - Material Feed Rate Multiplier 0.80

- T12 - On yoke 1, slot 2

- M221 - Update flow calculations

- S0.20 - Material Feed Rate Multiplier 0.20

- T14 - On yoke 1, slot 4