Difference between revisions of "Pulses per Microliter"

| (80 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

{| align="right" | |||

| __TOC__ | |||

|} | |||

This page will explain the various gearing on our different heads, and how we determine a baseline pulses per microliter value. | |||

Please note, these values are for Repetrel software and firmware family release version 4 and newer. These are NOT the right numbers for older versions. | |||

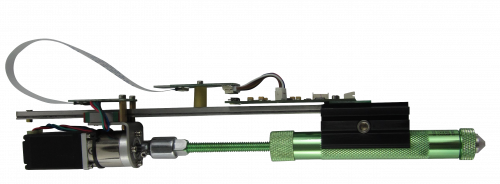

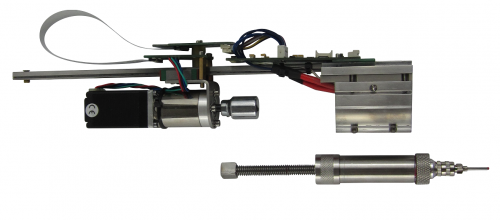

== The 27:1 EMO and VOL == | |||

The EMO and VOL heads each have: | |||

* A 1.8° stepping motor; | |||

** Running in 1/16th microstep mode; | |||

* A 27:1 planetary gear; | |||

* A 1:1 drive screw coupling; | |||

* A drive screw with a pitch of 18 threads per inch, or 1.411 thread per mm; | |||

* And a reservoir with a 17 mm diameter, or 227 mm<sup>2</sup> cross section. | |||

The table below explains how a certain number of pulses (or microsteps) on the motor will generate a certain volume displacement in the reservoir - the pulses/µL (or pulses/mm<sup>3</sup>) number that we need to control the material advance or displacement. Note that factors like viscosity, compressibility, and nozzle characteristics will introduce some delay from the time of displacement to the time of actual extrusion. | |||

The drive screw has a pitch of 18 threads per inch, or 1.411 mm per revolution. | {| border="1" class="wikitable" style="text-align: center;" cellpadding="0" | ||

|+ v4 Flow Calculations for the 27:1 EMO and VOL Heads | |||

|- | |||

| colspan="6" | [[File:EMO-horizontal.png|500px]] | |||

|- | |||

! Component | |||

! Motor | |||

! Gearing | |||

! Coupling | |||

! Drive Screw | |||

! Reservoir | |||

|- | |||

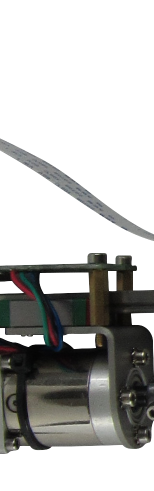

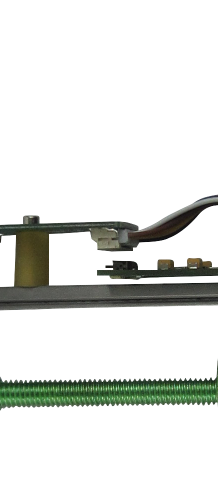

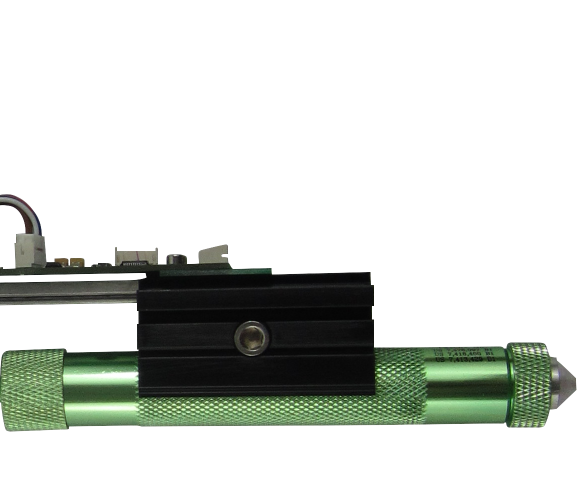

! Image | |||

| [[File:EH-motor.png|235px]] | |||

| [[File:EH-gear.png|154px]] | |||

| [[File:EH-coupling.png|127px]] | |||

| [[File:EH-screw.png|218px]] | |||

| [[File:EH-reservoir.png|583px]] | |||

|- | |||

! Details | |||

| NEMA 11, 1.8° stepping motor, <br> so 200 full steps = 1 revolution. | |||

1 pulse is a 1/16th microstep, <br> so 3200 pulses = 1 motor rev. | |||

| 27:1 planetary gear, <br> so 27 motor revs <br> = 1 output rev. | |||

| 1:1 direct coupling, <br> so no change <br> is introduced. | |||

| The drive screw has a pitch <br> of 18 threads per inch, or <br> 1.411 mm linear travel <br> per revolution. | |||

| The reservoir has a diameter of 17 mm, <br> so the cross sectional area is 227 mm<sup>2</sup>. | |||

Therefore, each revolution of the drive screw <br> displaces 1.411 x 227 or 317.8 mm<sup>3</sup> (or 317.8 µL) of volume. | |||

|- | |||

! 1 Rev <br> Calc. | |||

| 86,400 pulses = <br> 27 motor revs... | |||

| = 1 output rev... | |||

| = 1 screw rev... | |||

| = 1.411 mm linear advance... | |||

| = 317.8 µL displacement. | |||

|- | |||

! And so: | |||

! colspan="5" | 86,400 pulses = 317.8 µL, or 271.9 pulses/µL | |||

Experimentation in July 2020 produced average results of 271 pulses/µL | |||

|} | |||

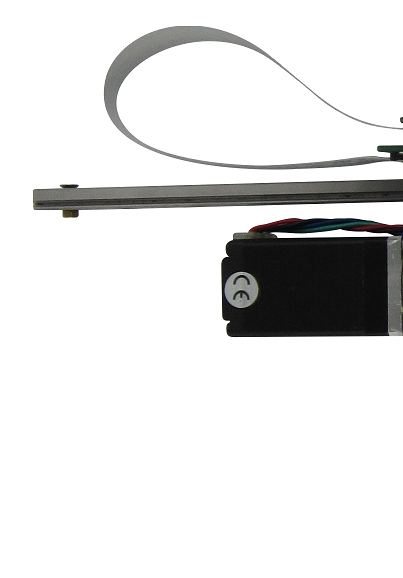

== The 100:1 EMO-XT, KR2, and TAM == | |||

The EMO-XT, KR2, and TAM heads each have: | |||

* A 1.8° stepping motor; | |||

** Running in 1/16th microstep mode; | |||

* A 1001 planetary gear; | |||

* A 1:1 drive screw coupling; | |||

* A drive screw with a pitch of 1 thread per mm; | |||

* And a reservoir with a 17.6 mm diameter, or 240 mm<sup>2</sup> cross section. | |||

The table below explains how a certain number of pulses (or microsteps) on the motor will generate a certain volume displacement in the reservoir - the pulses/µL (or pulses/mm<sup>3</sup>) number that we need to control the material advance or displacement. Note that factors like viscosity, compressibility, and nozzle characteristics will introduce some delay from the time of displacement to the time of actual extrusion. | |||

{| border="1" class="wikitable" style="text-align: center;" cellpadding="0" | |||

|+ v4 Flow Calculations for the 100:1 EMO-XT, KR2, and TAM Heads | |||

|- | |||

| colspan="6" | [[File:100-1_horiz.png|500px]] | |||

|- | |||

! Component | |||

! Motor | |||

! Gearing | |||

! Coupling | |||

! Drive Screw | |||

! Reservoir | |||

|- | |||

! Image | |||

| [[File:100-motor.png|403px]] | |||

| [[File:100-gear.png|165px]] | |||

| [[File:100-coupling.png|130px]] | |||

| [[File:100-screw.png|206px]] | |||

| [[File:100-reservoir.png|302px]] | |||

|- | |||

! Details | |||

| NEMA 11, 1.8° stepping motor, <br> so 200 full steps = 1 revolution. | |||

1 pulse is a 1/16th microstep, <br> so 3200 pulses = 1 motor rev. | |||

| 100:1 planetary gear, <br> so 100 motor revs <br> = 1 output rev. | |||

| 1:1 direct coupling, <br> so no change <br> is introduced. | |||

| The drive screw has a pitch <br> of 1 thread per mm, <br> or 1 mm linear travel <br> per revolution. | |||

| The reservoir has a diameter of 17.6 mm, <br> so the cross sectional area is 243 mm<sup>2</sup>. | |||

Therefore, each revolution of the drive screw <br> displaces 1 x 243 mm<sup>3</sup> (or 243 µL) of volume. | |||

|- | |||

! 1 Rev <br> Calc. | |||

| 320,000 pulses = <br> 100 motor revs... | |||

| = 1 output rev... | |||

| = 1 screw rev... | |||

| = 1 mm linear advance... | |||

| = 243 µL displacement. | |||

|- | |||

! And so: | |||

! colspan="5" | 320,000 pulses = 243 µL, or a theorectical 1317 pulses/µL | |||

Experimentation in July 2020 produced average results of 1297 pulses/µL | |||

|} | |||

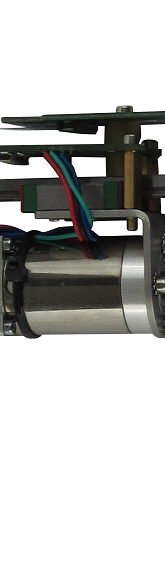

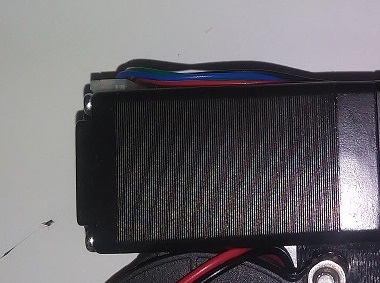

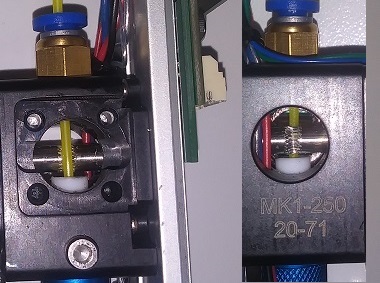

== The MK*-250 Heads == | |||

The MK1-250 and MK2-250 heads have: | |||

* A 1.8° stepping motor; | |||

** Running in 1/16th microstep mode; | |||

* And a hobbed (toothed) shaft with an effective diameter (due to hob depth) of 5 mm. | |||

The table below explains how a certain number of pulses (or microsteps) on the motor will generate a certain linear advancement of filament. | |||

{| border="1" class="wikitable" style="text-align: center;" cellpadding="0" | |||

|+ v4 Flow Calculations for the MK1-250 (shown) and MK2-250 Heads | |||

|- | |||

| colspan="3" | [[File:Mk1-250_noplate.jpg|390px]] [[File:Mk1-250_suckhole.jpg|390px]] | |||

|- | |||

! Component | |||

! Motor | |||

! Drive Shaft | |||

|- | |||

! Image | |||

| [[File:Mk1-250_noplate_ctrzoom_left.jpg]] | |||

| [[File:Mk1-250_noplate_ctrzoom_right.jpg]] | |||

|- | |||

! Details | |||

| NEMA 11, 1.8° stepping motor, <br> so 200 full steps = 1 revolution. | |||

1 pulse is a 1/16th microstep, <br> so 3200 pulses = 1 motor rev. | |||

| The hobs on the motor shaft have an effective diameter of 5 mm, <br> so using 2πr (or πØ) gives us an effective circumference of 15.7 mm. | |||

That means one motor rev gives us 15.7 mm of linear filament advance. | |||

|- | |||

! 1 Rev <br> Calc. | |||

| 1 colspan="2" | Since 1.75 mm filament has a cross section (πr<sup>2</sup>) of 2.4 mm, that means that for every linear mm of filament advanced, 2.4 mm<sup>3</sup> (or 2.4 μL) will be advanced. | |||

Therefore, 3200 pulses equals one revolution, which equals 15.7 mm of linear filament advancement, which equals 37.8 μL advanced. | |||

|- | |||

! And so: | |||

! colspan="2" | '''3200 pulses = 37.8 μL, or a theoretical 84.7 pulses/μL. | |||

Experimentation during 2020 has produced average results of 84.5 pulses/μL for ABS at 240 °C and 1800 mm/min.''' | |||

|- | |||

|} | |||

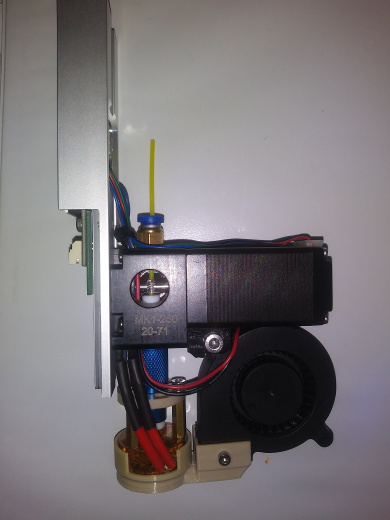

== The HT1-* heads == | |||

The | The HT1-250 and HT1-450 heads have: | ||

* A 1.8° stepping motor; | |||

** Running in 1/16th microstep mode; | |||

* A 5.14:1 planetary gear; | |||

* And a hobbed (toothed) shaft with an effective diameter (due to hob depth) of 11 mm. | |||

The table below explains how a certain number of pulses (or microsteps) on the motor will generate a certain linear advancement of filament. | |||

{| border="1" class="wikitable" style=" | {| border="1" class="wikitable" style="text-align: center;" cellpadding="0" | ||

|+ Flow Calculations for | |+ v4 Flow Calculations for the HT1-250 and HT1-450 Heads | ||

|- | |||

| colspan="4" | [[img]] [[img]] | |||

|- | |||

! Component | |||

! Motor | |||

! Gearing | |||

! Drive Shaft | |||

|- | |- | ||

| | ! Image | ||

| [[img]] | |||

| [[img]] | |||

| [[img]] | |||

|- | |- | ||

| | ! Details | ||

| NEMA 17, 1.8° stepping motor, <br> so 200 full steps = 1 revolution. | |||

1 pulse is a 1/16th microstep, <br> so 3200 pulses = 1 motor rev. | |||

| 5.18:1 planetary gear, <br> so 5.18 motor revs <br> = 1 output rev. | |||

| The hobs on the motor shaft have an effective diameter of 11.2 mm, <br> so using 2πr (or πØ) gives us an effective circumference of 35.2 mm. | |||

That means one output rev gives us 35.2 mm of linear filament advance. | |||

|- | |- | ||

| | ! rowspan="2" | 1 Rev <br> Calc. | ||

| 16,576 pulses <br> = 5.18 motor revs | |||

| 5.18 motor revs <br> = 1 output rev | |||

| Since 1.75 mm filament has a cross section (πr2) of 2.4 mm; that means <br> for every linear mm of filament advanced, 2.4 mm3 (or 2.4 μL) will be advanced. | |||

|- | |- | ||

| | | colspan="3" | Therefore, 16,576 pulses equals one revolution, which equals 35.2 mm of linear filament advancement, which equals 84.6 μL advanced. | ||

|- | |- | ||

| | ! And so: | ||

! colspan="3" | '''16,576 pulses = 84.6 μL, or a theoretical 192.4 pulses/μL. | |||

Experimentation during 2020 has produced average results of 175 pulses/μL for ABS at 240 °C and 1800 mm/min.''' | |||

|- | |- | ||

|} | |} | ||

Latest revision as of 17:58, 31 July 2020

This page will explain the various gearing on our different heads, and how we determine a baseline pulses per microliter value.

Please note, these values are for Repetrel software and firmware family release version 4 and newer. These are NOT the right numbers for older versions.

The 27:1 EMO and VOL

The EMO and VOL heads each have:

- A 1.8° stepping motor;

- Running in 1/16th microstep mode;

- A 27:1 planetary gear;

- A 1:1 drive screw coupling;

- A drive screw with a pitch of 18 threads per inch, or 1.411 thread per mm;

- And a reservoir with a 17 mm diameter, or 227 mm2 cross section.

The table below explains how a certain number of pulses (or microsteps) on the motor will generate a certain volume displacement in the reservoir - the pulses/µL (or pulses/mm3) number that we need to control the material advance or displacement. Note that factors like viscosity, compressibility, and nozzle characteristics will introduce some delay from the time of displacement to the time of actual extrusion.

The 100:1 EMO-XT, KR2, and TAM

The EMO-XT, KR2, and TAM heads each have:

- A 1.8° stepping motor;

- Running in 1/16th microstep mode;

- A 1001 planetary gear;

- A 1:1 drive screw coupling;

- A drive screw with a pitch of 1 thread per mm;

- And a reservoir with a 17.6 mm diameter, or 240 mm2 cross section.

The table below explains how a certain number of pulses (or microsteps) on the motor will generate a certain volume displacement in the reservoir - the pulses/µL (or pulses/mm3) number that we need to control the material advance or displacement. Note that factors like viscosity, compressibility, and nozzle characteristics will introduce some delay from the time of displacement to the time of actual extrusion.

The MK*-250 Heads

The MK1-250 and MK2-250 heads have:

- A 1.8° stepping motor;

- Running in 1/16th microstep mode;

- And a hobbed (toothed) shaft with an effective diameter (due to hob depth) of 5 mm.

The table below explains how a certain number of pulses (or microsteps) on the motor will generate a certain linear advancement of filament.

The HT1-* heads

The HT1-250 and HT1-450 heads have:

- A 1.8° stepping motor;

- Running in 1/16th microstep mode;

- A 5.14:1 planetary gear;

- And a hobbed (toothed) shaft with an effective diameter (due to hob depth) of 11 mm.

The table below explains how a certain number of pulses (or microsteps) on the motor will generate a certain linear advancement of filament.

| img img | |||

| Component | Motor | Gearing | Drive Shaft |

|---|---|---|---|

| Image | img | img | img |

| Details | NEMA 17, 1.8° stepping motor, so 200 full steps = 1 revolution. 1 pulse is a 1/16th microstep, |

5.18:1 planetary gear, so 5.18 motor revs = 1 output rev. |

The hobs on the motor shaft have an effective diameter of 11.2 mm, so using 2πr (or πØ) gives us an effective circumference of 35.2 mm. That means one output rev gives us 35.2 mm of linear filament advance. |

| 1 Rev Calc. |

16,576 pulses = 5.18 motor revs |

5.18 motor revs = 1 output rev |

Since 1.75 mm filament has a cross section (πr2) of 2.4 mm; that means for every linear mm of filament advanced, 2.4 mm3 (or 2.4 μL) will be advanced. |

| Therefore, 16,576 pulses equals one revolution, which equals 35.2 mm of linear filament advancement, which equals 84.6 μL advanced. | |||

| And so: | 16,576 pulses = 84.6 μL, or a theoretical 192.4 pulses/μL.

Experimentation during 2020 has produced average results of 175 pulses/μL for ABS at 240 °C and 1800 mm/min. | ||