Difference between revisions of "MK2-250"

Jump to navigation

Jump to search

| Line 22: | Line 22: | ||

== Description == | == Description == | ||

# The MK2-250 is fed filament from the top, through low friction tubing (2mm ID, 4mm OD) seated into a 4mm pneumatic fitting. | |||

# A 2mm OD PTFE guide tube accepts the filament. This tube has scalloped voids where the gibbed (toothed) portions of the drive shafts of two stepping motors engage the filament and feed it further down the tube. | |||

# At the bottom of the PTFE tube, the filament is routed to the brass nozzle, with which the PTFE tubing mates. | |||

# At the nozzle, heat is transferred to the filament, whereupon it is forced out through the brass nozzle. | |||

== Loading the Head onto the Printer == | == Loading the Head onto the Printer == | ||

Revision as of 16:22, 4 October 2016

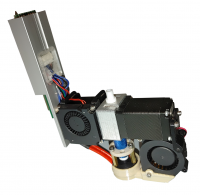

The MK2-250 is specially designed for flexible filaments, and works with flexible 1.75mm filaments which print at temperatures up to 250°C.

This includes the following materials:

- BendLay

- Flex 45

- MoldLay

- Ninjaflex

- EcoFlex PLA

- PlastInk_Rubber

Description

- The MK2-250 is fed filament from the top, through low friction tubing (2mm ID, 4mm OD) seated into a 4mm pneumatic fitting.

- A 2mm OD PTFE guide tube accepts the filament. This tube has scalloped voids where the gibbed (toothed) portions of the drive shafts of two stepping motors engage the filament and feed it further down the tube.

- At the bottom of the PTFE tube, the filament is routed to the brass nozzle, with which the PTFE tubing mates.

- At the nozzle, heat is transferred to the filament, whereupon it is forced out through the brass nozzle.

Loading the Head onto the Printer

asdf

Loading material into the Head

asdf

Default Parameters

asdf

Adjustments

asdf