Difference between revisions of "MK1-250"

Jump to navigation

Jump to search

| Line 53: | Line 53: | ||

== Loading material into the Head == | == Loading material into the Head == | ||

MK1-250 heads all ship with a remaining piece of filament from the last test print. We recommend leaving a few cm of filament above the head when changing heads. | |||

Unloading: | |||

# With the head properly seated and the emergency stop OUT, warm the head to the service temperature of the presently loaded material. | |||

# If presently loaded to a spool, press down on the blue pneumatic fitting and release the guide tubing; then cut the filament a few cm above the head. | |||

# Press the manual feed lever (at the top left of the head's 103 circuit board) to the left, retracting the filament. Retract until the filament comes free of the motor shaft, then remove. | |||

Loading: | |||

# Straighten (if needed) the last few cm of the new filament, which should be routed through the guide tubing. Insert it down through the pneumatic fitting on the top and centered between the two bearings, between the bearings and the drive shaft of the motor. | |||

# Press the manual feed lever to the right, advancing the filament until the lead end advances into the white PTFE tube. | |||

# In repetrel, click the motor on at 500 (pulses per minute) until the new filament advances to the melting zone and forces the old filament out. Advance about 30cm of filament, checking for smooth sides and uniform color. | |||

# Remove excess filament with tweezers. Seat the guide tubing. You are ready to go. | |||

== Default Parameters == | == Default Parameters == | ||

Revision as of 18:51, 4 October 2016

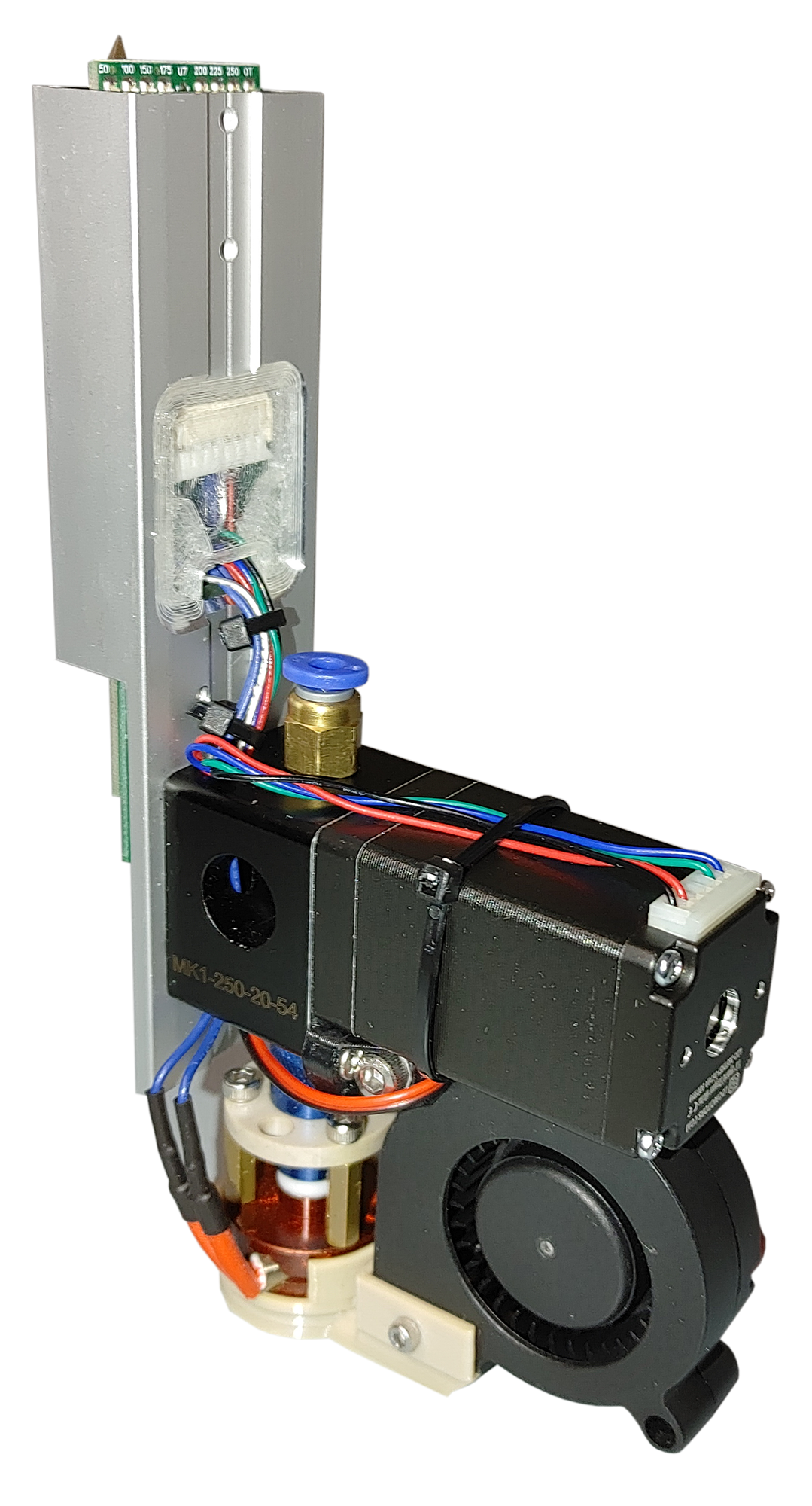

The MK1-250 is our primary workhorse print head, and works for standard (rigid) 1.75mm filaments which print at temperatures up to 250°C.

This includes the following materials:

- ABS (Acrylonitrile Butadiene Styrene)

- Flame Retardant ABS

- ABS - PC Alloy

- Conductive ABS

- Smart ABS

- HIPS (High-Impact PolyStyrene)

- LayBrick

- LayWoo-d3

- Nylon

- Taulman 618, 645, 910

- PC (PolyCarbnoate)

- PET (PolyEthylene Terephthalate)

- PETG PolyEthylene Terephthalate Glycol-modified)

- PLA (Polylactic acid)

- Conductive PLA

- SS PLA (Stainless Steel infused)

- PP (PolyPropylene)

- PVA (PolyVinyl Alcohol)

- T-Glase

Description

- The MK1-250 is fed filament from the top, through low friction tubing (2mm ID, 4mm OD) seated into a 4mm pneumatic fitting.

- A cover plate maintains pressure, via a spring, against a rod with two bearings; these bearings keep the filament pressed against and centered on the gibbed (toothed) portion of the drive shaft of the stepping motor.

- Beneath this, the filament enters into a 2mm OD PTFE guide tube, which leads the filament to the brass nozzle, with which the PTFE tubing mates.

- At the nozzle, heat is transferred to the filament, whereupon it is forced out through the brass nozzle.

Loading the Head onto the Printer

As with all Hyrel heads, the following process should be followed:

- Start with a level bed and Repetrel running and connected to the printer.

- Load the gibs on the Head into the gib slots on the Yoke from above and slide the head down into place; the last mm of travel should be done gently, ensuring that the electrical connector seats properly (firmly and completely) into the receiving connector.

- Ensure the LEDs on the print head are flashing - this means the Head is communicating with the Motion Controller.

- Tighten the thumbscrew in the rear, to prevent the head from moving relative to the Yoke.

- If the Head doesn't show up in Repetrel, press and release the RESET button on the front of the printer.

- Once the Head is shown in repetrel, proceed to setting your Z-Zero position.

Loading material into the Head

MK1-250 heads all ship with a remaining piece of filament from the last test print. We recommend leaving a few cm of filament above the head when changing heads.

Unloading:

- With the head properly seated and the emergency stop OUT, warm the head to the service temperature of the presently loaded material.

- If presently loaded to a spool, press down on the blue pneumatic fitting and release the guide tubing; then cut the filament a few cm above the head.

- Press the manual feed lever (at the top left of the head's 103 circuit board) to the left, retracting the filament. Retract until the filament comes free of the motor shaft, then remove.

Loading:

- Straighten (if needed) the last few cm of the new filament, which should be routed through the guide tubing. Insert it down through the pneumatic fitting on the top and centered between the two bearings, between the bearings and the drive shaft of the motor.

- Press the manual feed lever to the right, advancing the filament until the lead end advances into the white PTFE tube.

- In repetrel, click the motor on at 500 (pulses per minute) until the new filament advances to the melting zone and forces the old filament out. Advance about 30cm of filament, checking for smooth sides and uniform color.

- Remove excess filament with tweezers. Seat the guide tubing. You are ready to go.

Default Parameters

asdf

Adjustments

asdf

Firmware

asdf

Maintenance

asdf