Difference between revisions of "Main Page"

| Line 659: | Line 659: | ||

===== '''Research Papers''' Citing Hyrel Cold Flow ===== | ===== '''Research Papers''' Citing Hyrel Cold Flow ===== | ||

* [https://pubs.acs.org/doi/abs/10.1021/acs.jpcc.8b00580 Tailoring the Porosity and Microstructure of Printed Graphene Electrodes via Polymer Phase Inversion] by a team from [http://northwestern.edu Northwestern University] | |||

* [https://static1.squarespace.com/static/59581b474c8b03b8a580b4ae/t/5a5c280bec212d764ffc3203/1515989014007/Bioink+Paper.pdf Injectable Nanocomposite Hydrogels for Cell Delivery and Bioprinting] by a team by a team from three disciplines of [http://www.tamu.edu/ Texas A&M University]. | * [https://static1.squarespace.com/static/59581b474c8b03b8a580b4ae/t/5a5c280bec212d764ffc3203/1515989014007/Bioink+Paper.pdf Injectable Nanocomposite Hydrogels for Cell Delivery and Bioprinting] by a team by a team from three disciplines of [http://www.tamu.edu/ Texas A&M University]. | ||

* [https://www.researchgate.net/profile/Manik_Chandra_Biswas2/publication/317318891_Feasibility_of_Printing_3D_Bone_Models_for_Education_at_TUCVM/links/5931e797aca272fc55093f49/Feasibility-of-Printing-3D-Bone-Models-for-Education-at-TUCVM.pdf Feasibility of Printing 3D Bone Models for Education at TUCVM] at [https://www.researchgate.net/ ResearchGate] | * [https://www.researchgate.net/profile/Manik_Chandra_Biswas2/publication/317318891_Feasibility_of_Printing_3D_Bone_Models_for_Education_at_TUCVM/links/5931e797aca272fc55093f49/Feasibility-of-Printing-3D-Bone-Models-for-Education-at-TUCVM.pdf Feasibility of Printing 3D Bone Models for Education at TUCVM] at [https://www.researchgate.net/ ResearchGate] | ||

Revision as of 13:27, 3 April 2018

Welcome to Hyrel!

With literally thousands of materials to print on the Hyrel Printer, we have broken down the list of materials into logical groups based on their printing temperature and type of head used to print them.

A quick intro to many of the functions of a Hyrel printer can be found here.

If you are planning on using the heads which photoinitiate crosslinking, make sure you specify the correct wavelength of LED for your material.

A standard material printing data sheet has been created for many of the materials that have been internally tested; you can access this data by clicking here.

Always be sure of what material you are using, and what will be off-gassed.

Our current price list can be found here.

Testimonials

We are happy to share testimonials from the following institutions:

- School of Electrical and Computer Engineering, Georgia Institute of Technology

- Bioplastics Research Center, University of Massachusetts, Lowell

- School of Materials Science and Engineering, Georgia Institute of Technology

- Tooling Division, AO Smith Water Products Company

Software and Firmware

Our equipment runs our proprietary Repetrel software and firmware. This was not done to be difficult, but because we didn't want to be restricted by the limitations of other printers. This is how we have the ability to adjust things like the Z position and material flow rate during a print. For a more in-depth look, please see the Repetrel page. To download and install, please see the Software page.

Hardware

There are two categories: Printers and Heads (or Accessories).

Printers

As of May, 2017, Hyrel Printers are available in the following models: Hydras are our larger, gantry models; Systems are our tabletop, enclosed models; and Engines are the smaller, unenclosed models - available in High Resolution (HR) and Standard Resolution (SR) versions.

All models use our Repetrel software and any slicer (Slic3r support provided). Each model comes with a Windows PC, either tablet or full desktop style. We operate our print heads via CANbus.

Comparison

The following chart compares and contrasts the various models:

| Designation | Hydra Freestanding (Floor) Models formerly the 16A |

Hydra Bench top Model formerly the 17A |

Benchtop, Enclosed | Desktop, Unenclosed | Desktop, High Precision | ||

|---|---|---|---|---|---|---|---|

| Hydra 430 | Hydra 640 | Hydra 645 | Hydra 340 | System 30M | Engine SR | Engine HR | |

| Target Users |

Industrial Manufacturing | Commercial Manufacturing | Laboratory Research | Budget Research | Biological Research | ||

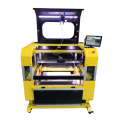

| Image | |||||||

| Placement Mechanism |

Freestanding (Floor) Model Gantry Design |

Benchtop Model Gantry Design |

Benchtop Model Knee Design |

Desktop Model Knee Design |

Desktop Model Knee Design | ||

| Exterior Dimensions, XxYxZ (closed) |

48x35x50 in 120x88x125 cm |

48x35x60 in 120x88x153 cm |

41x27x28 in 104x69x71 cm |

34x16x32 in 565x405x810 cm |

13x21x22 in 330x530x560 cm |

13x24x22 in 330x600x560 cm | |

| Power Requirements |

15A / 110VAC / 60 Hz 8A / 220VAC / 50Hz |

15A / 110VAC / 60 Hz 8A / 220VAC / 50Hz |

10A / 110VAC / 60 Hz 5A / 220VAC / 50Hz |

10A / 110VAC / 60 Hz 5A / 220VAC / 50Hz |

10A / 110VAC / 60 Hz 5A / 220VAC / 50Hz | ||

| Build Volume | 16x12x10 in 400x300x250 mm |

24x16x10 in 600x400x250 mm |

24x16x20 in 600x400x500 mm |

12x16x10 in 300x400x250 mm |

8x8x8 in 200x200x200 mm |

8x8x8 in 200x200x200 mm |

4x4x4 in 100x100x100 mm |

| Bed Temperatures |

120°C 200°C option |

120°C | 75°C | 75°C | 75°C -10C option | ||

| X/Y Printing Speeds |

Up to 50 mm/sec | Up to 50 mm/sec | Up to 30 mm/sec | Up to 30 mm/sec | Up to 15 mm/sec | ||

| Enclosure | Heated to 55°C | Heated to 55°C | Enclosed *Opt Heated to 55°C |

Unenclosed | Unenclosed | ||

| Motion Control | 3-Phase with Closed-Loop Feedback |

3-Phase with Closed-Loop Feedback |

0.9° Stepping Motor | 0.9° Stepping Motor | 0.9° Stepping Motor | ||

| Positional Resolution X/Y/Z in µm |

6 / 6 / 1 | 6 / 6 / 1 | 5 / 5 / 1 | 5 / 5 / 1 | 1.25 / 1.25 / 1 | ||

| Positional Accuracy X/Y/Z in µm |

60 / 60 / 10 | 60 / 60 / 10 | 50 / 50 / 10 | 50 / 50 / 10 | 12 / 12 / 10 | ||

| Positional Repeatability X/Y/Z in µm |

60 / 60 / 10 | 60 / 60 / 10 | 50 / 50 / 10 | 50 / 50 / 10 | 12 / 12 / 10 | ||

| Precise X/Y Output for Bioplots |

100 µm lines 200 µm spacing |

100 µm lines 200 µm spacing |

100 µm lines 200 µm spacing |

100 µm lines 200 µm spacing |

50 µm lines 100 µm spacing | ||

| Precise Z output for Bioplots |

25 µm layers | 25 µm layers | 25 µm layers | 25 µm layers | 25 µm layers | ||

| Tool Positions Optional |

Five Ten |

Five | Four | Four | Five | ||

| Cold Flow Options |

All EMO, COD, SDS, CSD, DSD and SMH Heads | ||||||

| Warm Flow Options |

All VOL, VCD, KRA and KCD Heads | ||||||

| Hot Flow Options |

All MK1-250, MK2-250 and MK1-450 Heads | ||||||

| Low Power Laser Options |

5w, 808nm, AlGaAs Diode and/or 6w, 450nm, GaN Diode | ||||||

| High Power Laser Options |

40w ~10 µm, CO2 80w, ~10µm, CO2 |

Not Applicable | Not Applicable | Not Applicable | Not Applicable | ||

| Spindle Tool Compatibility |

Standard Three-Phase |

Standard | Standard | Standard | Not Applicable | ||

| Other Options |

Quiet Storm Fan, Microscope | ||||||

The Hydra Series

The Hydra series formerly the Model 16A and 17A has hard resolution (with encoder feedback) of 20 microns in the X and Y, and 0.8 microns in the Z in standard mode. In microstepping mode, we can achieve soft resolution of 4 microns in the X and Y. It comes standard with two tool positions, but can take additional yokes to handle more.

There are four models, as detailed above. The differences are:

- The Hydra 340 sits on a countertop, has a 300x400x250mm build volume, and has no CO2 laser option.

- The Hydra 430 stands on the floor, has a 400x300x250mm build volume, and has 40w and 80w CO2 laser options.

- The Hydra 640 stands on the floor, has a 600x400x250mm build volume, and has 40w and 80w CO2 laser options.

- The Hydra 645 stands on the floor, has a 400x400x500mm build volume, and has 40w and 80w CO2 laser options.

Overview of the Hydra line

Overview of the Hydra line

The System 30M, 30, and 23

Systems are enclosed Detailed information is on the Systems page. The System 30M replaced the System 30, which replaced the System 23. For you history buffs and Kickstarters.

The Engines

Engines are open-air models. Engines can take up to four heads at once, either working cooperatively on a one print, or making duplicate copies of a small print at the same time. Build volume is 200mm x 200mm x 200mm (X/Y/Z). Detailed information is on the Engines page.

Print Heads

Comparison

The folLowing chart compares and contrasts the various heads:

| Designation | Material | Viscosity | Gear Ratio | Volume | Reservoir | Temperature | UV LEDs? | Other |

|---|---|---|---|---|---|---|---|---|

| MK1-250 | 1.75mm Filament | Standard | n/a | n/a | n/a | Up to 250°C | n/a | For Standard Material |

| MK2-250 | 1.75mm Filament | Flexible | n/a | n/a | n/a | Up to 250°C | n/a | For Flexible Material |

| MK1-450 | 1.75mm Filament | Exotic | n/a | n/a | n/a | 300 to 450°C | n/a | For High-Temp Material |

| SDS-05 | Liquid, Gel | Low | 3:1 | 05cc | Polypropylene | Ambient | Optional | n/a |

| SDS-10 | Liquid, Gel | Low | 3:1 | 10cc | Polypropylene | Ambient | Optional | n/a |

| SDS-30 | Liquid, Gel | Low | 3:1 | 30cc | Polypropylene | Ambient | Optional | n/a |

| SDS-60 | Liquid, Gel | Low | 3:1 | 60cc | Polypropylene | Ambient | Optional | n/a |

| DSD-50 | Two-part Mixtures | Low | 3:1; 1:1 Ratio | 25cc each part | Polypropylene | Ambient | Optional | n/a |

| SMH-2 | Two-part Mixtures | Low | 3:1; Variable Ratio | Up to 60cc each part | Depends on feeding heads | Ambient | Optional | n/a |

| CSD-05 | Liquid, Gel | Low | 3:1 | 05cc | Polypropylene | Ambient | Yes | n/a |

| CSD-10 | Liquid, Gel | Low | 3:1 | 10cc | Polypropylene | Ambient | Yes | n/a |

| CSD-30 | Liquid, Gel | Low | 3:1 | 30cc | Polypropylene | Ambient | Yes | n/a |

| CSD-60 | Liquid, Gel | Low | 3:1 | 60cc | Polypropylene | Ambient | Yes | n/a |

| HSD-30-BD | Liquid, Gel | Low | 3:1 | 30cc | Polypropylene | Up to 75°C | Optional | n/a |

| HSD-10-Ardes | Liquid, Gel | Low | 3:1 ? | 30cc | Polyamide | Up to 130°C | Optional | n/a |

| CHS-30 | Liquid, Gel | Low | 3:1 | 30cc | Polypropylene | Up to 75°C | Yes | n/a |

| EMO-25 | Liquid, Gel, Paste | Low to Medium | 19:1 | 25cc | Aluminum | Ambient | Optional | n/a |

| COD-25 | Liquid, Gel, Paste | Low to Medium | 19:1 | 25cc | Aluminum | Ambient | Yes | n/a |

| VOL-25 | Liquid, Gel, Paste | Low to Medium | 51:1 | 25cc | Aluminum | Up to 100°C | Optional | n/a |

| VCD-25 | Liquid, Gel, Paste | Low to Medium | 51:1 | 25cc | Aluminum | Up to 100°C | Yes | n/a |

| KRA-25 | Paste, Clay, Hot Glue | Medium to High | 100:1 | 15cc | Stainless | Up to 200°C* | Optional | n/a |

| KCD-25 | Paste, Clay, Hot Glue | Medium to High | 100:1 | 15cc | Stainless | Up to 200°C* | Yes | n/a |

| KR2-25 | Paste, Clay, Hot Glue | Medium to High | 100:1 | 15cc | Stainless | Up to 200°C* | Optional | n/a |

| KC2-25 | Paste, Clay, Hot Glue | Medium to High | 100:1 | 15cc | Stainless | Up to 200°C* | Yes | n/a |

| LA5-808 | Dark, Opaque | Laser | n/a | n/a | n/a | n/a | n/a | 5w, 808nm |

| LA6-450 | Opaque | Laser | n/a | n/a | n/a | n/a | n/a | 6w, 4550nm |

| LI40 | Translucent | Laser | n/a | n/a | n/a | n/a | n/a | 40w, 10μm |

| LI80 | Translucent | Laser | n/a | n/a | n/a | n/a | n/a | 80w, 10μm |

| ST1 | Waxes, Plastics | Spindle Tool | n/a | n/a | n/a | n/a | n/a | 5,000 rpm with no load |

The Cold Flow Process

Cold Flow is our term for fluid or emulsified (non-filament-based) materials which are deposited at room temperature, with or without UV Crosslinking.

For more details, see the Cold and Warm Flow page.

Materials for Cold Flow

The following materials can be printed from Cold Flow heads. Note that more viscous materials may not be suitable for plastic syringes or smaller luer tips.

- 3P Quick Cure Clay

- Adhesives

- Clay, Generic

- Epoxy, Two-part

- Fimo

- Glue

- Kato

- Metal Clay, including Precious Metal Clay (PMC)

- Modeling Clay

- PEG PolyEthylene Glycol

- Porcelain

- Plasticine

- Play-Doh

- Resins

- RTV Silicone

- Sculpey

- Sugru

Heads for Cold Flow

Cold Flow is available through the following heads:

The following table compares the properties of the various Cold Flow heads:

| Head | Container | Capacity | Nozzle | UV Crosslinking |

|---|---|---|---|---|

| EMO-25 | Aluminum | 25cc | 1.5mm, 2.0mm, Luer | No |

| COD-25 | Aluminum | 25cc | Luer | Yes |

| SDS-5 | Syringe | 05cc | Luer | No |

| CSD-5 | Syringe | 05cc | Luer | Yes |

| SDS-10 | Syringe | 10cc | Luer | No |

| CSD-10 | Syringe | 10cc | Luer | Yes |

| SDS-30 | Syringe | 30cc | Luer | No |

| CSD-30 | Syringe | 30cc | Luer | Yes |

| SDS-60 | Syringe | 60cc | Luer | No |

| CSD-60 | Syringe | 60cc | Luer | Yes |

Research Papers Citing Hyrel Cold Flow

- Tailoring the Porosity and Microstructure of Printed Graphene Electrodes via Polymer Phase Inversion by a team from Northwestern University

- Injectable Nanocomposite Hydrogels for Cell Delivery and Bioprinting by a team by a team from three disciplines of Texas A&M University.

- Feasibility of Printing 3D Bone Models for Education at TUCVM at ResearchGate

- Design and Additive Manufacturing of Multi-Permeability Magnetic Cores, in 2017 IEEE Energy Conversion Congress and Exposition (ECCE)

- Combustion-Assisted Photonic Annealing of Printable Graphene Inks via Exothermic Binders, by a team from Northwestern Univeristy

- In Vitro Evaluation of 3D Bbioprinted Tri-Polymer Network Scaffolds for Bone Tissue Regeneration, by Stephanie Bendtsen and Mei Wei, in The Journal of Biomedical Materials Research Part A

- Self-Actuating 3D Printed Packaging for Deployable Antennas, The Institute of Electrical and Electronics Engineers, Incorporated (IEEE)

- Enabling Process Intensification via 3D Printing of Catalytic Structures by Muxina Konarova (and others), University of Queensland

- 3D Bioprinting for Musculoskeletal Applications by Alexander Popov, Sara Malferrari, & Deepak M Kalaskar in Future Medicine

- UV-assisted 3D-printing of Soft Ferrite Magnetic Components for Power Electronics Integration by Dr. Y. Yan (and others), Virginia Tech

- Alginate Hydrogels for Bone Tissue Regeneration by Stephanie T. Bendtsen of The University of Connecticut

- Fabrication of Biomimetic Bone Grafts with Multi-Material 3D Printing by Nicholas Sears et. al., of the Biomedical Engineering Department of Texas A&M University.

- Additive Manufacturing of Magnetic Components for Heterogeneous Integration by Dr. Y. Yan (and others), Virginia Tech

- Nanoengineered Eggshell–Silver Tailored Copolyester Polymer Blend Film with Antimicrobial Properties by the Department of Materials Science and Engineering and the Department of Pathobiology, College of Veterinary Medicine of Tuskegee University

- Additive Manufacturing of Magnetic Components for Heterogeneous Integration by Dr. Y. Yan (and others), Virginia Tech

- Die-Less MIM-style Additive Manufacturing with Controlled Porosity: A Proof of Concept by the Department of Materials Science and Engineering of Lehigh University

- 3D Printed Energetics by the Weapons and Combat Systems Division of the Australian Department of Defense

- Development of 3D printed Ceramic scaffolds for Treatment of Segmental Bone Defects from The Biomaterials and Tissue Engineering Research Unit of the Aerospace, Mechanical and Mechatronic Engineering Department of The University of Sydney

- Graduate Abstract: Dynamic increase in matrix stiffness promotes invasive tumor phenotype in vivo from multiple organizations, at BioMaterials.org

- 3D Printing of High Porosity, Biodegradable Foams with Cure on Dispense - Presentation by Elizabeth Cosgriff-Hernández of Department of Biomedical Engineering, Texas A&M University

- Design Methodology and Materials for Additive Manufacturing of Magnetic Components - PhD Thesis of Y. Yan, Virginia Tech

- Bioprinting Defined Heterogeneous Cellular Microenvironments from The Biomaterials and Tissue Engineering Research Unit of the Aerospace, Mechanical and Mechatronic Engineering Department of The University of Sydney

- A Novel Approach to Integrating 3D/4D Printing and Stretchable Conductive Adhesive Technologies for High Frequency Packaging Applications

- Additive Manufacturing of Planar Inductor for Power Electronics Applications

- Bioactive Nanoengineered Hydrogels for Bone Tissue Engineering: A Growth-Factor-Free Approach in The American Chemical Society's ACS Nano

- Design and Fabrication of 3D Printed Scaffolds with a Mechanical Strength Comparable to Cortical Bone to Repair Large Bone Defects in Nature.com's Scientific Reports

- Emulsion Inks for 3D Printing of High Porosity Materials in the Macromolecular Journals

The Warm Flow Process

Warm Flow is our term for fluid or emulsified (non-filament-based) materials which are deposited at up to 150°C, with or without UV Crosslinking, depending on the head.

PCL and other medium temperature material can be printed directly from Pellets the size of small peas. If you pulverize or powder your polymer, it is possible to pre-mix the material dry and test different alloys of plastics.

For more details, see the Cold and Warm Flow page.

Materials for Warm Flow

The following materials can be printed from Warm Flow heads. Note that more viscous materials may not be suitable for plastic syringes or smaller luer tips, or may print more easily at higher temperatures.

- Adhesives

- Fimo

- Kato

- Glue

- PCL

- Plasticine

- Resins

- Sculpey

- Wax

Heads for Warm Flow

Warm Flow is available through the following heads:

The following table compares the properties of the various Warm Flow heads:

| Head | Max Temp | Container | Capacity | Nozzle | UV Crosslinking |

|---|---|---|---|---|---|

| VOL-25 | 100°C | Aluminum | 25cc | 1.5mm, 2.0mm, Luer | No |

| VCD-25 | 100°C | Aluminum | 25cc | Luer | Yes |

| KRA-15 | 150°C | Stainless | 15cc | 1.5mm, 2mm, Luer | No |

| KCD-15 | 150°C | Stainless | 15cc | Luer | Yes |

Research Papers Citing Hyrel Warm Flow

- Shear-Thinning and Thermo-Reversible Nanoengineered Inks for 3D Bioprinting in the American Chemical Society's Applied Materials & Interfaces Journal

- Nanoengineered Colloidal Inks for 3D Bioprinting in The American Chemical Society's Langmuir

- 4D Printing of Liquid Crystal Elastomers in The American Chemical Society's ACS Applied Materials & Interfaces

- Influence of Shear Thinning and Material Flow on Robotic Dispensing of PEG in The American Chemical Society's ACS Nano

The Hot Flow Process

Hot Flow is our term for filament-based materials which are deposited at up to 450°C, depending on the head. This process has also been referred to as FFF for Fused Filament Fabrication, or FDM for Fused Deposition Modeling. As of November, 2016, our Hot Flow heads are only for 1.75mm filaments.

For more details, see the Hot Flow page.

Materials for Hot Flow

The following materials can be printed from Hot Flow heads. Note that depending on the characteristics of your material, one head will be a better match than the others. See the "Recommended For" column in the table below.

- ABS, Acrylonitrile Butadiene Styrene

- BendLay

- FilaFlex

- Flex45

- LayBrick

- LayWood

- NinjaFlex

- Nylon

- PC, PolyCarbonate

- PEEK, PolyEther Ether Ketone

- PET, PolyEthylene Terephthalate

- PETG, PolyEthylene Terephthalate Glycol-modified

- PLA, PolyLactic Acid

- PlastInk Rubber

- PP, PolyPropylene

- PVA, PolyVinyl Alcohol

- T-Glase

Heads for Hot Flow

Hot Flow is available through the following heads:

The following table compares the properties of the various Hot Flow heads, including which heads are recommended for which materials. The MK1 heads drive matieral from one side, with a spring-loaded bearing system to maintain pressure and positioning. The MK2 heads drive the material from both sides, and are designed for more flexible filaments.

| Head | Min Temp | Max Temp | Filament Type | Nozzle | Recommended For |

|---|---|---|---|---|---|

| MK1-250 | 150°C | 250°C | Standard | .35mm, .50mm, .75mm, 1.0mm | ABS, LayBrick, LayWood, Nylon, PET, PETG, PETT, PLA, PP, PVA, T-Glase |

| MK2-250 | 150°C | 250°C | Flexible | .35mm, .50mm, .75mm, 1.0mm | BendLay, FilaFlex, Flex45, NinjaFlex, PlastInk Rubber |

| MK1-450 | 300°C | 450°C | Engineering | .50mm | PC, PEEK |

Research Papers Citing Hyrel Hot Flow

- Fabrication and Properties of Novel Polymer-Metal Composites using Fused Deposition Modeling by the Mechanical Engineering Staff at Worcester Polytechnic Institute

- NANOSATC-BR2, 2 unit CUBESAT, Power Analysis, Solar Flux Prediction, Design and 3D Printing of the Flight Model from the UFSM & INPE’S NANOSATC-BR, CUBESAT Development Program by a team from the Federal University of Santa Maria (UFSM), Brasil.

- A Preliminary Study of Conductive Filaments Printed Via Fused Filament Fabrication by Smruti Ranjan Sahoo at Rochester Institute of Technology

- Tensile Mechanical Properties of Polypropylene Composites Fabricated by Material Extrusion, a reviewed paper of the Solid Freeform Fabrication Symposium 2017.

- Effect of Process Parameters and Shot Peening on Mechanical Behavior of ABS Parts Manufactured by Fused Filament Fabrication (FFF), a reviewed paper of the Solid Freeform Fabrication Symposium 2017.

- Hybrid Processes in Additive Manufacturing in the Journal of Manufacturing Science and Engineering of the American Society of Mechanical Engineers

- Effects of Material Properties on Warpage in Fused Deposition Modeling Parts in The International Journal of Advanced Manufacturing Technology

- Thermal and Mechanical Properties of 3D Printed Boron Nitride – ABS Composites, in Applied Composite Materials

- Review of Batteryless Wireless Sensors Using Additively Manufactured Microwave Resonators in Sensors, a Journal of the Multidisciplinary Digital Publishing Institute

- Dynamical Majorana edge modes in a broad class of topological mechanical systems by The New Jersey Institute of Technology

- A Low-Cost, Single Platform, Hybrid Manufacturing System for RF Passives, The Institute of Electrical and Electronics Engineers, Incorporated (IEEE)

- Button-Shaped RFID Tag Combining Three-Dimensional and Inkjet Printing Technologies, The IET Digital Library.

- Demonstration and Characterization of Fully 3D-printed RF Structures, The Institute of Electrical and Electronics Engineers, Incorporated (IEEE)

- Infill Dependent 3D-Printed Material Based on NinjaFlex Filament for Antenna Applications, The Institute of Electrical and Electronics Engineers, Incorporated (IEEE)

- A Novel Strain Sensor Based on 3D Printing Technology and 3D Antenna Design, The Institute of Electrical and Electronics Engineers, Incorporated (IEEE)

- A Novel 3-D Printed Loop Antenna Using Flexible NinjaFlex Material for Wearable and IoT Applications, The Institute of Electrical and Electronics Engineers, Incorporated (IEEE)

- RF Characterization of 3D Printed Flexible Materials - NinjaFlex Filaments, The European Microwave Association (EuMA)

- Nano-Material Based Flexible Radio Frequency Sensors for Wearable Health and Environment Monitoring: Designs and Prototypes Utilizing 3D/Inkjet Printing Technologies, A Dissertation Presented to The Academic Faculty of The School of Electrical and Computer Engineering at Georgia Tech

Other Accessories

Accessories other than print heads are available, some of which take a tool position.

For more details, see the Other Accessories page.

Tool Position Accessories

Lasers

Hot-swappable Lasers are available in the following configurations:

- The LA5-808 is a diode laser, 5W at 808nm, and due to its wavelength, it is best suited for darker material.

- The LA6-450 is a diode laser 6W at 450nm, and performs well on opaque material of any color.

- The LI40 is an integrated 40w CO2 laser, and performs well on translucent as well as opaque material; available on our Hydra models only.

- The LI80 is an integrated 80w CO2 laser, and performs well on translucent as well as opaque material; available on our Hydra models only.

The Reflectivity and Transparency or Translucency of your material will have a great impact on the effectiveness of the laser. Safety glasses are included with each laser.

Spindle Tools

The ST1 is intended for light drilling and routing operations (especially circuit board work), and provides between 500 and 5000 RMP (depending on load) to a 1/8" chuck. Our Repetrel software can process Gerber and DRL files for the Spindle Tool and/or the Lasers.

The ST3 is presently in testing, but provides more power; available on our Hydra models only.

Other Tool Position Accessories

The following accessories each take up a tool position while performing more passive functions:

- The Inspector microscope provides magnification.

- The Quiet Storm fan provides additional cooling.

- The Tramming Tool, provided with every printer, is used to level the build surface.

Non-Tool Position Accessories

The following non-head accessories are also available:

- The Feed Chamber Cooling Fan mounts on Hot Flow heads to provide additional cooling to the feed chamber. This is desirable with low temperature filaments like PLA.

- The Printer Support Kit is included with every printer, and includes a build plate, blue tape, and a variety of handy tools like tweezers, razors, and a spatula.

- The SDK | Software Developer's Kit provides hardware, software, and the source code for developing your own firmware for your own compatible heads.

- The LTK | Luer Tip Kit provides an EMO to Luer adapter and a variety of luer lock needles.

- The Syringe Kit provides syringes in quantity.

- The Drill Bit Kit provides an assortment of drilling bits and end mills for the Spindle Tool.

- The Filament Kit provides a variety of filaments to get you started with your printer.