Difference between revisions of "Pulses per Microliter"

| Line 46: | Line 46: | ||

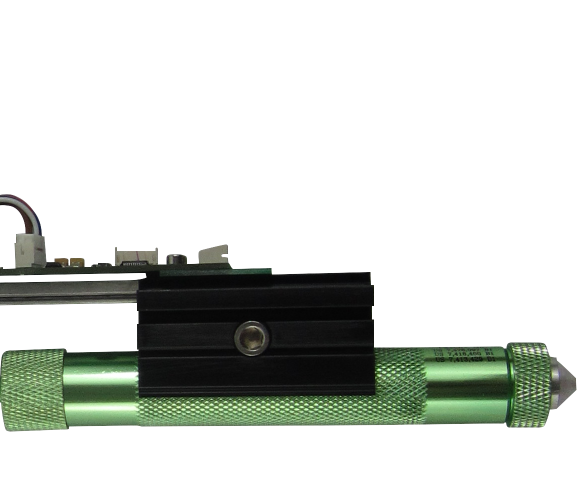

| The drive screw has a pitch <br> of 18 threads per inch, or <br> 1.411 mm linear travel <br> per revolution. | | The drive screw has a pitch <br> of 18 threads per inch, or <br> 1.411 mm linear travel <br> per revolution. | ||

| The reservoir has a diameter of 17 mm, <br> so the cross sectional area is 227 mm^2. | | The reservoir has a diameter of 17 mm, <br> so the cross sectional area is 227 mm^2. | ||

Therefore, each revolution of the drive screw <br> displaces 1.411 x 227 or 317.8 mm^3 (or 317.8 µL) | Therefore, each revolution of the drive screw <br> displaces 1.411 x 227 or 317.8 mm^3 (or 317.8 µL) of volume. | ||

|} | |} | ||

Revision as of 16:49, 27 July 2020

This is to explain the various gearing on our different heads.

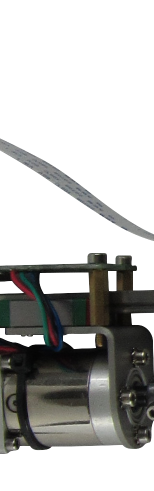

EMO and VOL

The EMO and VOL heads both have a 27:1 gear ratio.

360 degrees equals one revolution of the motor.

Each full step is 1.8 degrees, so 200 full steps per revolution of the extrusion motor.

With 1/16th microstepping, that means 3200 microsteps per revolution of the extrusion motor.

One revolution of the extrusion motor equals one revolution of the drive screw (direct connection).

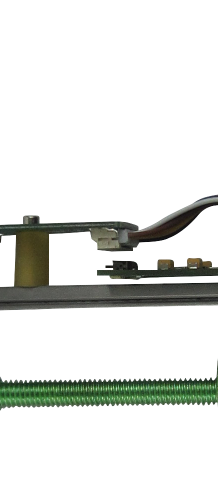

The drive screw has a pitch of 18 threads per inch, or 1.411 mm per revolution.

So...

3200 pulses times 27 equals 86,400 pulses (or microsteps) on the motor will deliver one revolution of the drive shaft, which moves the plunger in 1.4 mm in the cylinder.

The cylinder has a diameter of 17 mm, so the cross sectional area is 227 mm^2.

One revolution then displaces 1.4 mm of 227 mm^2 cross section, or 317.8 mm^3, or 317.8 µL.

Therefore, 86,400 pulses = 317.8 µL, or ~ 272 pulese/µL.