Difference between revisions of "MK1-250"

Jump to navigation

Jump to search

| Line 57: | Line 57: | ||

asdf | asdf | ||

== Firmware == | |||

asdf | |||

== Maintenance == | |||

Revision as of 16:51, 4 October 2016

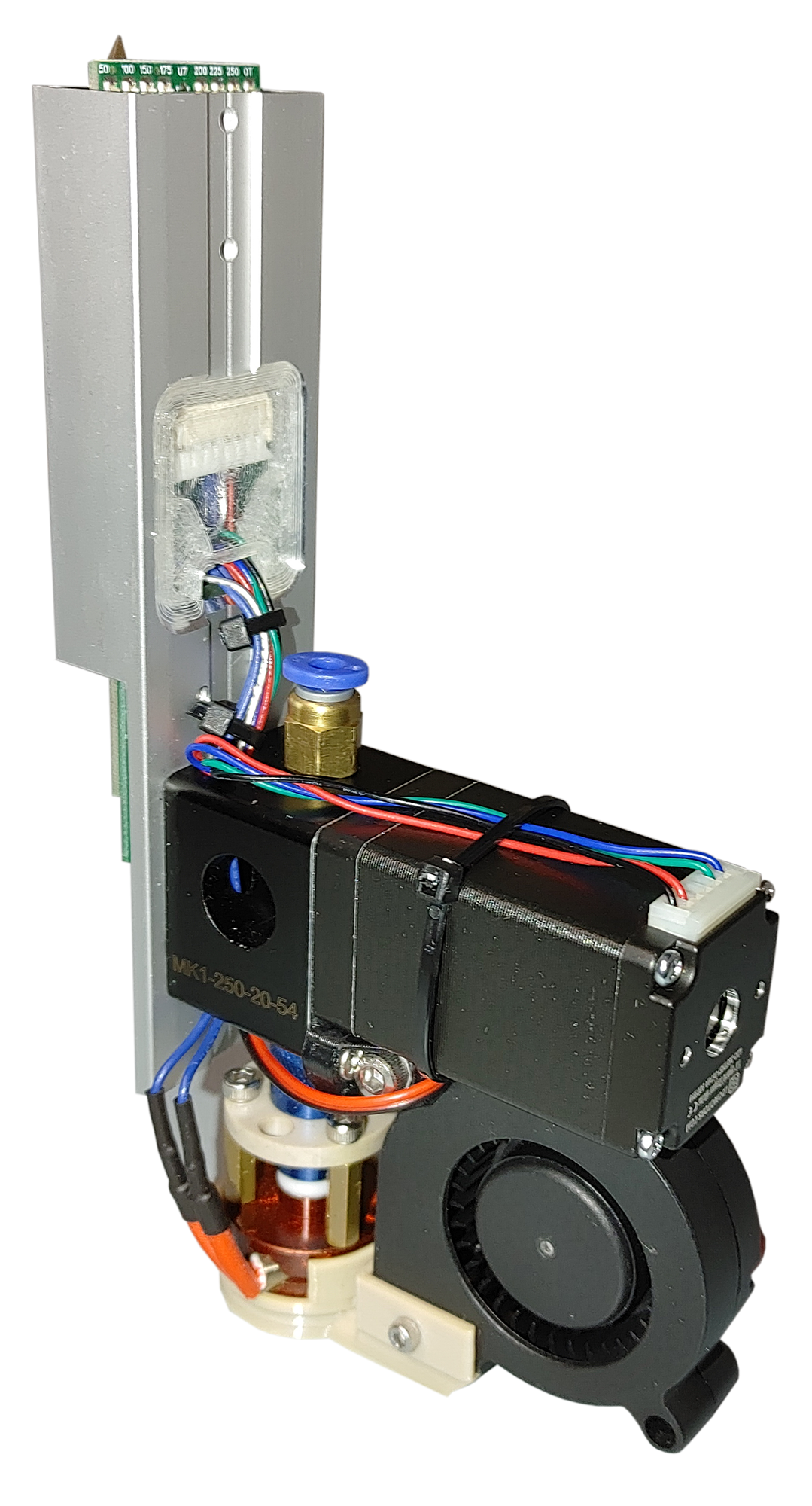

The MK1-250 is our primary workhorse print head, and works for standard (rigid) 1.75mm filaments which print at temperatures up to 250°C.

This includes the following materials:

- ABS (Acrylonitrile Butadiene Styrene)

- Flame Retardant ABS

- ABS - PC Alloy

- Conductive ABS

- Smart ABS

- HIPS (High-Impact PolyStyrene)

- LayBrick

- LayWoo-d3

- Nylon

- Taulman 618, 645, 910

- PC (PolyCarbnoate)

- PET (PolyEthylene Terephthalate)

- PETG PolyEthylene Terephthalate Glycol-modified)

- PLA (Polylactic acid)

- Conductive PLA

- SS PLA (Stainless Steel infused)

- PP (PolyPropylene)

- PVA (PolyVinyl Alcohol)

- T-Glase

Description

- The MK1-250 is fed filament from the top, through low friction tubing (2mm ID, 4mm OD) seated into a 4mm pneumatic fitting.

- A cover plate maintains pressure, via a spring, against a rod with two bearings; these bearings keep the filament pressed against and centered on the gibbed (toothed) portion of the drive shaft of the stepping motor.

- Beneath this, the filament enters into a 2mm OD PTFE guide tube, which leads the filament to the brass nozzle, with which the PTFE tubing mates.

- At the nozzle, heat is transferred to the filament, whereupon it is forced out through the brass nozzle.

Loading the Head onto the Printer

As with all Hyrel heads, the following process should be followed:

Loading material into the Head

asdf

Default Parameters

asdf

Adjustments

asdf

Firmware

asdf