Difference between revisions of "Pulses per Microliter"

Jump to navigation

Jump to search

| Line 5: | Line 5: | ||

The EMO and VOL heads each have: | The EMO and VOL heads each have: | ||

* A 1.8° stepping motor; | |||

** Running in 1/16th microstep mode; | |||

* A 27:1 planetary gear; | |||

* A 1:1 drive screw coupling; | |||

* A drive screw with a pitch of 18 threads per inch, or 1.411 thread per mm; | |||

* And a reservoir with a 17 mm diameter, or 227 mm<sup>2</sup> cross section. | |||

The table below explains how a certain number of pulses (or microsteps) on the motor will generate a certain volume displacement in the reservoir - the pulses/µL number that we need to control the material flow. | The table below explains how a certain number of pulses (or microsteps) on the motor will generate a certain volume displacement in the reservoir - the pulses/µL number that we need to control the material flow. | ||

Revision as of 17:24, 27 July 2020

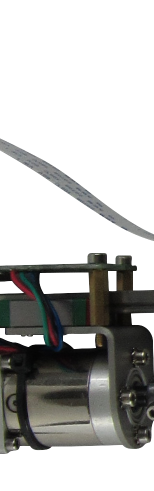

This is to explain the various gearing on our different heads.

Calculating Pulses/µL for the 27:1 EMO and VOL

The EMO and VOL heads each have:

- A 1.8° stepping motor;

- Running in 1/16th microstep mode;

- A 27:1 planetary gear;

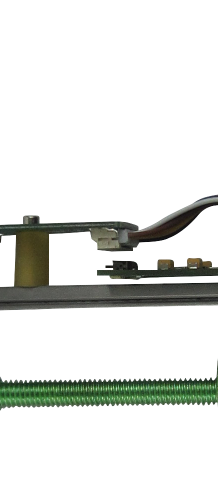

- A 1:1 drive screw coupling;

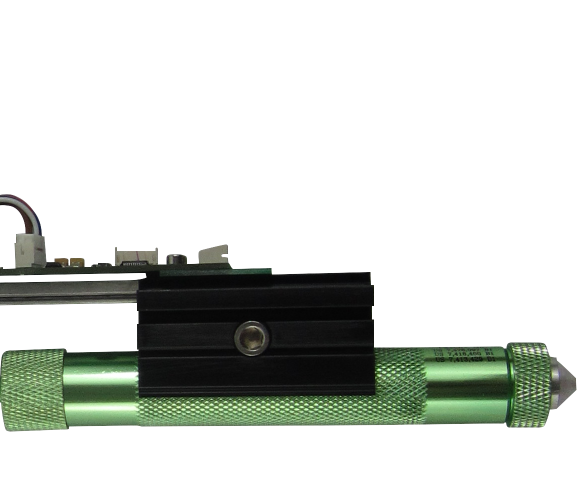

- A drive screw with a pitch of 18 threads per inch, or 1.411 thread per mm;

- And a reservoir with a 17 mm diameter, or 227 mm2 cross section.

The table below explains how a certain number of pulses (or microsteps) on the motor will generate a certain volume displacement in the reservoir - the pulses/µL number that we need to control the material flow.