T v5

Understanding the T on versions 5 and later (the enlightenment).

The T

With the release of Repetrel v5, we are happy to announce that the means of addressing heads for T Commands and T Variables within M Commands has been unified. Finally, T0 always means the first head on the first yoke, regardless of how or why we are referring to it.

Chart of Addresses

Below are details of addressing for each tool position on each model printer.

Using the T with the ESR and 30M

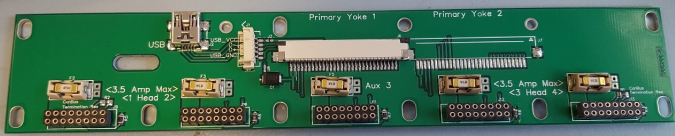

The Engine, Standard Resolution and the System 30M use the following configuration.

Note: some very, very early models had two slots on the left and two on the right, but counting available tool positions from the left, the positions are the same.

| Yoke Image |

| ||||

|---|---|---|---|---|---|

| Description | 1st Slot | No Slot | 2nd Slot | 3rd Slot | 4th Slot |

| T Designation | T0 | N/A | T1 | T2 | T3 |

| Global Variable | T10 or T41 | ||||

Using the T with the EHR and 16A (Single Yoke)

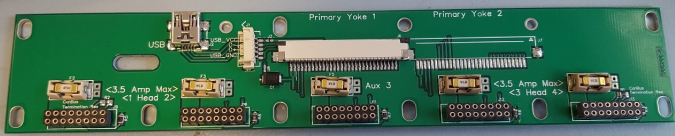

The Engine, High Resolution and the single-yoke Hydra 16A use the following configuration.

| Yoke Image |

| ||||

|---|---|---|---|---|---|

| Description | 1st Slot | 2nd Slot | 3rd Slot | 4th Slot | 5th Slot |

| T Desingation | T0 | T1 | T2 | T3 | T4 |

| Global Variable | T10 or T41 | ||||

| Description | T Designation | |

|---|---|---|

| All Devices | T40 | |

| Yoke 1, All Slots | T41 | |

| Yoke 2, All Slots | T42 | |

| CO2 Laser | T21 | |

| 3-Phase Spindle | T20 | |

| Primary Bed/Chamber | T24 | |

| Secondary Bed/Chamber | T25 | |

| All Beds/Chambers | n/a | M# T90 |

Using the T with the 16A (Dual Yoke)

Dual-yoke Hydra 16A units use the following configuration.

| Description | T Command | T Variable |

|---|---|---|

| All Devices | n/a | M# T0 |

| All Heads | n/a | M# T100 |

| Yoke 1, All Slots | n/a | M# T10 |

| Yoke 2, All Slots | n/a | M# T20 |

| CO2 Laser | T11 | M# T41 |

| 3-Phase Spindle | T12 | M# T26 |

| Primary Bed/Chamber | n/a (T13) | M# T91 |

| Secondary Bed/Chamber | n/a (T14) | M# T92 |

| All Beds/Chambers | n/a | M# T90 |

Default Mode

By default, when you start a job (click the "Print" button), Repetrel will scan the yoke(s), detecting heads serially from left to right, registering which head is in which slot, and "focus" on the first head it detects. Many users only print with one head and use gcode that does not explicitly direct commands to any particular head. The effect of this is that the gcode will be executed with the only head loaded, regardless of what slot it is in. However, you do have the option - and, when printing with multiple heads, the requirement - to explicitly direct Repetrel's "focus" to a particular head, either for the entire job, or changing "focus" to different heads at different times.

At the start of the job, Repetrel sends the head-specific data to the motion controller; this is done behind the scenes, but if you enable XMIT echoing on the Interface/COM tab, you can see what gets sent. Additionally, the header and gcode together are written to C:\PrintHistory\HyrelPrintFile.gocde - and this is the file you should send us for help toubleshooting.

One Head Loaded

In the following example, I have one MK1-250 head loaded in the first slot on the left, slot 1 (tool focus command T0, but variable T11):

M6 T11 O1 X0 Y0 Z0 M721 S10000 E100 P-15 T11 M722 S10000 E100 P20 T11 M221 S1.0 T11 P77 W0.5 Z0.3 M728 T11 S0

These commands are decoded and executed by the printer as follows:

- M6 (Declare Head Offsets)

- T11 (far left slot)

- O1 (offset stored in register "O1")

- X0 (offsets in X)

- Y0 (offsets in Y)

- Z0 (offsets in Z)

- M721 (Set Unprime Values)

- S10000 (10,000 pps)

- E100 (100 pulses)

- P-15 (15ms before end of print move sequence)

- T11 (for far left head)

- M722 (Set Prime Values)

- S10000 (10,000 pps)

- E100 (100 pulses)

- P20 (20ms before start of print move sequence)

- T11 (for far left head)

- M221 (Set Flow Rate)

- S1.0 (flow multiplier of 1.0)

- T11 (for far left head)

- P77 (77 pulses per microliter)

- W0.5 (0.5mm nozzle)

- Z0.3 (0.3mm layer thickness - note that your gcode M756 will overwrite this value)

- M728 (set motor current boost)

- T11 (far left slot)

- S0 (off)

See the entries for these commands, below, for more details.

Two Heads Loaded

In the following example, I have one MK1-250 head loaded in the second slot from the left, slot 2 (tool focus command T1, but variable T12), and one SDS-05 head loaded in the third slot from the left, slot 3 (tool focus command T2, but variable T13):

M6 T12 O2 X0 Y0 Z0 M721 S10000 E100 P-15 T12 M722 S10000 E100 P20 T12 M221 S1.0 T12 P77 W0.5 Z0.3 M728 T12 S0 M6 T13 O3 X0 Y0 Z0 M721 S10000 E160 P-100 T13 M722 S10000 E200 P100 T13 M221 S1.0 T13 P81.0 W1.6 Z0.3 M728 T13 S0

See above for full details.

Explicit Mode

Although we don't generally recommend keeping heads loaded if they will be unused on the current job, you might want to do this. At the beginning of your gcode, force focus with a T command in the gcode before your first print move. We recommend doing this before any movements, in case your head will collide with the bed without the offset. A simple T1 (or for whichever head you want focused on) will accomplish this.

If you are printing with two heads (for two stl files from different heads, or if you want infill or support from a different head than the one printing perimeters), the slicer will generate T commands where needed.

If you are doing a clone/parallel/slave print (two heads executing the same code at the same time), see the M703 entry, below, for more details.

Here are some examples:

T0

This command is decoded and executed by the printer as follows:

- T0 (Switch to far left head, and invoke all flow, prime, unprime, and offset parameters)

T3

This command is decoded and executed by the printer as follows:

- T3 (Switch to fourth head from the left, and invoke all flow, prime, unprime, and offset parameters)

Error Messages

So, in an effort to conform with standard CNC gcode practices, we now check which heads are called out with T commands in your gcode when it is loaded or refreshed, and we compare that with which tool positions on the yoke actually have heads. If there is any mismatch, warning message popups will appear.

If you have your heads called out in your gcode and the same tool positions loaded with heads, you will not see these warnings.

Gcodes

M702 Establish Clone Squad

M702 establishes a "Clone Squad" - a group of heads that will perform the same exact (extrusion) commands.

Note that an M30 decommissions any clone squads that were in effect.

Usage

M702 T# S#

Parameters

T# is the head from which flow (pulse/prime/etc) settings will be copied and applied to the group; this head does not need to be in the group S# is the clone squad number designation and must be in the range 50 - 57

Example

M702 T# S#

This command is decoded and executed by the printer as follows:

- M702 (establish clone squad)

- T# (using flow values from target head)

- S# (designate squad number)

M703 Add to Clone Squad

M703 adds a single head to the Clone Squad we established with an M702. Use this command multiple times to add multiple heads to the squad.

Usage

M703 T# S#

Parameters

T# is the target head to add to the squad S# is the clone squad number designation and must be in the range 50 - 57

Example

M702 T# S#

This command is decoded and executed by the printer as follows:

- M703 (add to clone squad)

- T# (target head)

- S# (target clone squad)

M704 Remove from Clone Squad

M704 removes a single head to the Clone Squad we established with an M702 and loaded with one or more M703s. Use this command multiple times to remove multiple heads from the squad.

Usage

M703 T# S#

Parameters

T# is the target head to remove from the squad S# is the clone squad number designation and must be in the range 50 - 57

Example

M702 T# S#

This command is decoded and executed by the printer as follows:

- M703 (remove from clone squad)

- T# (target head)

- S# (target clone squad)