Hydra 16A

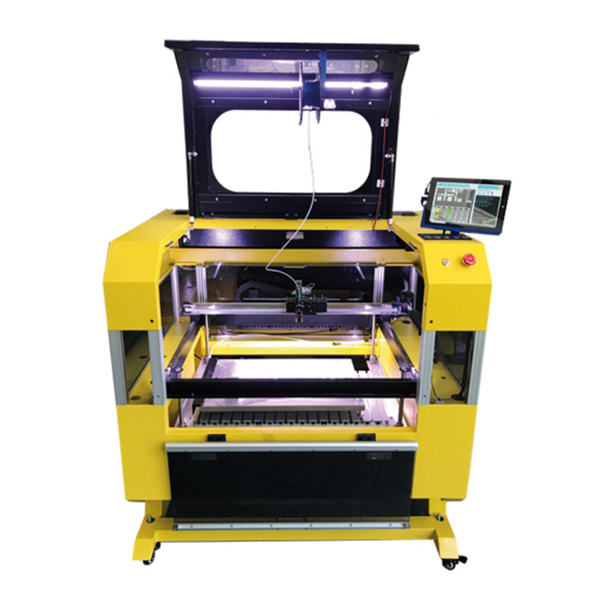

The Hydra 16A is our large format machine.

History

- The Hydra 16A was introduced in 2015, with a 200C bed option

- The CO2 laser and 4th axis options were introduced in 2016

- The 4th/5th axis combo was introduced in 2018

Technical Data

Technical specifications and accessory compatibility for printers currently shipping are detailed in the comparison chart on the Printer Overview page.

Internals

Here is an explanation of the internal electronics of the Hydra 16A; click any images for larger versions:

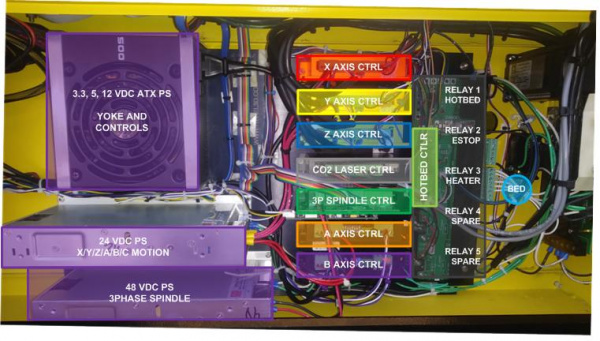

Main Panel

The Main Panel has the Power Supplies, Controllers, Encoders, and Relays.

- The Left Side:

- The ATX Power Supply provides 3.3, 5, and 12 VDC power to the processor, lights, and most heads loaded on the yoke.

- The 24 VDC Power Supply provides 24 VDC power to the motion motors - X, Y, Z, A, and B.

- The 48 VDC Power Supply provides 48 VDC power to the 3-phase spindle tool.

- The Center:

- The X Axis Encoder controls motion and monitors for errors in this axis.

- The Y Axis Encoder controls motion and monitors for errors in this axis.

- The Z Axis Encoder controls motion and monitors for errors in this axis.

- The optional CO2 Laser Driver controls the CO2 Laser.

- The optional 3-Phase Spindle Driver controls the 3-Phase Spindle Tool.

- The optional A Axis Encoder controls motion and monitors for errors in this axis.

- The optional B Axis Encoder controls motion and monitors for errors in this axis.

- The Right Side:

- The Hotbed Controller controls the heated or chilled build platform and the emergency stop.

- The Relays control power to:

- The Hotbed (or Coldbed)

- The Emergency Stop

- The Chamber Heater

- (spare)

- (spare)

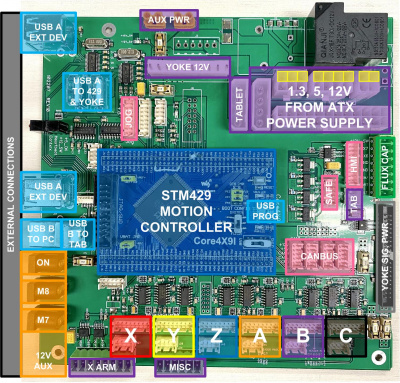

Front Panel

The Front Panel has the Tablet Interface Board (with STM429 Motion Controller) and External Ports.