FAQs

So, some folks have questions about how they can make certain changes in their prints. I will answer the most frequently asked questions below.

The following all apply to v1, v2, and v3 of Repetrel.

How do the various settings all work together?

This is pretty easy, once you know the flow.

- You set the recipes for the parameters (extrusion width, infill patterns/density, print speed, layer thickness, head/bed temperatures, etc.; save the recipes (with descriptive names - don't overwrite the originals), and close the recipe editor.

- You highlight your properly scaled, positioned, rotated stl and select the print, printer, and extruder (filament) recipes to use, and go to Process > Slice with Slic3r.

- You review your gcode to ensure that you got what you were hoping to get; review the layer-by-layer rendering as well as the actual settings for temperature, layer thickness (Z moves and M756 flow settings), etc.

- You load the print head. Default settings from the head are displayed in Repetrel.

- You ensure that the data on the print head reflect your preheat temperature (if any) and proper nozzle diameter (and prime/unprime settings if your custom material requires adjustment) - these settings should be flashed to the head.

- You do any preparation (preheating, bed treatment, priming material, etc).

- You press Print. Upon pressing print, the following happens:

- Head settings are sent from repetrel to the printer.

- Gcode is sent from repetrel to the printer. Since gcode is sent second, this will overwrite any head-based settings if gcode has different values

How do I change nozzle sizes?

There are two places where we consider nozzle size:

1. On the head, we use the number you have for nozzle diameter to make our flow calculations. See Flow Rate for details about how we determine how fast to spin the motor so that you get the proper volume per second of deposition. This image is for printing with a 14# (fourteen gauge, or 1.6mm ID) luer needle:

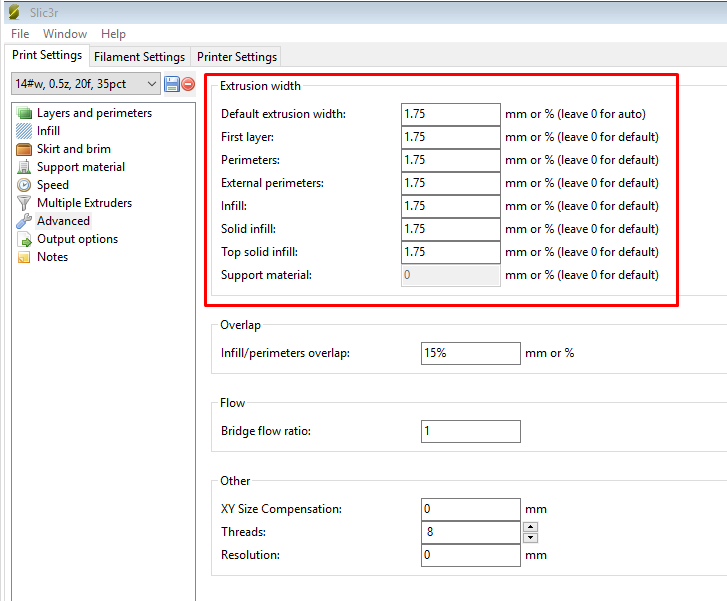

2. In the recipe, we use the extrusion width numbers to determine how far apart to place each bead of material. We expect your extrusion width to be 10% wider than your nozzle diameter (to allow for a nice sandbag-shaped cross section). This image is for printing with a 14# (fourteen gauge, or 1.6mm ID) luer needle:

How do I change head temperature?

This applies to everything we print, from PLA to Porcelain to PEEK.

Please note that we do NOT use any other variable relating to nozzle diameter. Not Bridge Flow Ratio. Not Nozzle Diameter. Not Extrusion Multiplier. All of these variables affect the E values in your gcode. Which we then ignore.