Overview

Welcome to Hyrel!

With literally thousands of materials to print on the Hyrel Printer, we have broken down the list of materials into logical groups based on their printing temperature and type of head used to print them.

A quick intro to many of the functions of a Hyrel printer can be found here.

If you are planning on using the heads which photoinitiate crosslinking, make sure you specify the correct wavelength of LED for your material.

A standard material printing data sheet has been created for many of the materials that have been internally tested; you can access this data by clicking here.

Always be sure of what material you are using, and what will be off-gassed.

Our current price list can be found here.

Software and Firmware

Our equipment runs our proprietary Repetrel software and firmware. This was not done to be difficult, but because we didn't want to be restricted by the limitations of other printers. This is how we have the ability to adjust things like the Z position and material flow rate during a print. For a more in-depth look, please see the Repetrel page. To download and install, please see the Software page.

Hardware

There are two categories: Printers and Heads (or Accessories).

Printers

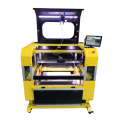

Hyrel Printers are available in the following models: Hydras are our larger, gantry models; Systems are our tabletop, enclosed models; and Engines are the smaller, unenclosed models - available in Standard Resolution (SR) and High Resolution (HR, for bioprinting) versions.

All models use our Repetrel software and any slicer (Slic3r support provided). Each model comes with a Windows PC, either tablet or full desktop style. We operate our print heads via CANbus.

Comparison

The following chart compares and contrasts the various models:

| Designation | Hydra 16A Freestanding Heated |

Benchtop, Enclosed Heating Optional |

Desktop, Unenclosed | Desktop, High Precision Unenclosed | ||

|---|---|---|---|---|---|---|

| 16AS Hydra Standard |

16AT Hydra Tall |

System 30M | Engine SR | Engine HR | ||

| Target Users |

Industrial Manufacturing | Laboratory Research | Budget Research | Biological Research | ||

| Image | ||||||

| Placement Mechanism |

Freestanding (Floor) Model Gantry Design |

Benchtop Model Knee Design |

Desktop Model Knee Design | |||

| Exterior Dimensions, XxYxZ (closed) |

48x35x50 in 120x88x125 cm |

48x35x60 in 120x88x153 cm |

34x16x32 in 565x405x810 cm |

13x21x22 in 330x530x560 cm |

13x24x22 in 330x600x560 cm | |

| Power Requirements |

15A / 110VAC / 60 Hz 8A / 220VAC / 50Hz |

10A / 110VAC / 60 Hz 5A / 220VAC / 50Hz | ||||

| Build Volume | 16x12x10 in 400x300x250 mm or 24x16x10 in 600x400x250 mm |

16x12x20 in 600x400x500 mm or 24x16x20 in 600x400x500 mm |

8x8x8 in 200x200x200 mm |

4x4x4 in 100x100x100 mm | ||

| Bed Temperatures |

120°C - 200°C option - sub-ambient option Note that 200°C beds larger than 400x300mm require 230VAC for optimal heating. |

80°C | 100°C - sub-ambient option | |||

| X/Y Printing Speeds |

Up to 60 mm/sec | Up to 30 mm/sec | Up to 15 mm/sec | |||

| Enclosure | Heated to 55°C | Enclosed *Opt Heated to 55°C |

Unenclosed | |||

| Motion Control | 3-Phase with Closed-Loop Feedback |

0.9° Stepping Motor | ||||

| Positional Resolution X/Y/Z in µm |

6 / 6 / 1 | 5 / 5 / 1 | 1.25 / 1.25 / 1 | |||

| Positional Accuracy X/Y/Z in µm |

60 / 60 / 10 | 50 / 50 / 10 | 12 / 12 / 10 | |||

| Positional Repeatability X/Y/Z in µm |

60 / 60 / 10 | 50 / 50 / 10 | 12 / 12 / 10 | |||

| Precise X/Y Output for Bioplots |

100 µm lines 200 µm spacing |

50 µm lines 100 µm spacing | ||||

| Precise Z output for Bioplots |

25 µm layers | |||||

| Tool Positions Optional |

Five Ten |

Four | Five | |||

| Reservoir Ambient Options |

All EMO, SDS, DSD and SMH Heads | |||||

| Reservoir Temp Ctrl Options |

All VOL, KRA, TAM, RSD, and HSD Heads | |||||

| Filament Options |

All MK1-250, MK2-250 and MK1-450 Heads | |||||

| Low Power Laser Options |

6w, 450nm, GaN Diode and 2w, 450nm GaN Diode | |||||

| High Power Laser Options |

40w ~10 µm, CO2 | Not Applicable | ||||

| Spindle Tool Compatibility |

Standard Three-Phase |

Standard | Not Applicable | |||

| Max Axes | X, Y, Z, A, B, C | X, Y, Z | ||||

| Pick & Place Compatibility |

Yes | No | ||||

| Other Options |

Quiet Storm Fan, Microscope | |||||

The Hydra Series

The Hydra 16A models have hard resolution (with encoder feedback) of 20 microns in the X and Y, and 0.8 microns in the Z in standard mode. In microstepping mode, we can achieve soft resolution of 4 microns in the X and Y. It comes standard with two tool positions, but can take additional yokes to handle more.

There are three models, as detailed above. The differences are:

- The Hydra 16A-S (standard) has a 250mm Z and stands on the floor, with the following options:

- Can take a bed at 400x300mm or 600x400mm at 120°C or 200°C, or a sub-ambient bed;

- Can take the 40W CO2 laser and 5W, 450nm diode laser;

- Can take the Pick and Place setup; and

- Can take the 3-Phase and 1-Phase spindle tools.

- The Hydra 16A-T (tall) has a 500mm Z and stands on the floor, with the following options:

- Can take a bed at 400x300mm or 600x400mm at 120°C or 200°C, or a sub-ambient bed;

- Can take the 5W, 450nm diode laser (NO CO2 LASER);

- Can take the Pick and Place setup; and

- Can take the 3-Phase and 1-Phase spindle tools.

Overview of the Hydra line

Overview of the Hydra line

The System 30M, 30, and 23

Systems are enclosed Detailed information is on the Systems page. The System 30M replaced the System 30, which replaced the System 23. For you history buffs and Kickstarters.

The Engines

Engines are open-air models. Engines can take up to four heads at once, either working cooperatively on a one print, or making duplicate copies of a small print at the same time. Build volume is 200mm x 200mm x 200mm (X/Y/Z). Detailed information is on the Engines page.

Modular Heads

Modular Heads Comparison

The following chart compares and contrasts the various extrusion heads:

| Designation | Image | Material | Viscosity | Motor and Gear Ratio |

Volume | Reservoir | Temperature | UV LEDs? | Other |

|---|---|---|---|---|---|---|---|---|---|

| MK1-250 |

|

1.75mm Filament | Standard | NEMA 11 1:1 |

n/a | n/a | Up to 250°C | n/a | For Standard Material |

| MK1-450 |

|

1.75mm Filament | Exotic | NEMA 11 1:1 |

n/a | n/a | 300 to 450°C | n/a | For High-Temp Material |

| MK2-250 |

|

1.75mm Filament | Flexible | NEMA 11 1:1 |

n/a | n/a | Up to 250°C | n/a | For Flexible Material |

| HT1-250 |

|

1.75mm Filament | Standard | NEMA 17 5.18:1 Higher Torque Available |

n/a | n/a | Up to 250°C | n/a | For Standard Material |

| HT1-450 |

|

1.75mm Filament | Exotic | NEMA 17 5.18:1 Higher Torque Available |

n/a | n/a | 300 to 450°C | n/a | For High-Temp Material |

| HT3-250 |

|

2.85mm Filament | Standard | NEMA 17 14:1 Higher Torque Available |

n/a | n/a | Up to 250°C | n/a | For Standard Material |

| HT3-450 |

|

2.85mm Filament | Exotic | NEMA 17 14:1 Higher Torque Available |

n/a | n/a | 300 to 450°C | n/a | For High-Temp Material |

| SDS-1 |

|

Liquid, Gel | Up to 100,000 cP | NEMA 11 3:1 |

1cc | Polypropylene | Ambient | Optional | Disposable Reservoir Normal Torque |

| SDS-05 |

|

Liquid, Gel | Up to 100,000 cP | NEMA 11 3:1 |

05cc | Polypropylene | Ambient | Optional | Disposable Reservoir Normal Torque |

| SDS-10 |

|

Liquid, Gel | Up to 100,000 cP | NEMA 11 3:1 |

10cc | Polypropylene | Ambient | Optional | Disposable Reservoir Normal Torque |

| SDS-30 |

|

Liquid, Gel | Up to 100,000 cP | NEMA 11 3:1 |

30cc | Polypropylene | Ambient | Optional | Disposable Reservoir Normal Torque |

| SDS-30XT |

|

Liquid, Gel | Up to 300,000 cP | NEMA 17 25.9:1 |

30cc | Polypropylene | Ambient | Optional | Disposable Reservoir Extra Torque |

| SDS-60 |

|

Liquid, Gel | Up to 100,000 cP | NEMA 11 3:1 |

60cc | Polypropylene | Ambient | Optional | Disposable Reservoir Normal Torque |

| SDS-60XT |

|

Liquid, Gel | Up to 300,000 cP | NEMA 17 25.9:1 |

60cc | Polypropylene | Ambient | Optional | Disposable Reservoir Extra Torque |

| SDS-150XT | 50px | Liquid, Gel | Up to 300,000 cP | NEMA 17 25.9:1 |

60cc | Polypropylene | Ambient | Optional | Disposable Reservoir Extra Torque |

| DSD-50 | 50px | Two-part Mixtures | Up to 100,000 cP | NEMA 11 1:1 |

25cc each part | Polypropylene | Ambient | Optional | Disposable Reservoirs Normal Torque 1:1, 2:1, 3:1 Blend Ratios |

| SMH-2 |

|

Two-part Mixtures | Up to 100,000 cP | NEMA 11 1:1 Gear Ratio |

Up to 150cc each part | Depends on feeding heads | Ambient | Optional | *Fed by other heads Variable Blend Ratios |

| HSD-10-Ardes |

|

Liquid, Gel | Up to 100,000 cP | NEMA 11 1:1 |

10cc | Polyamide | Up to 100°C | Optional | n/a |

| HSD-30-BD |

|

Liquid, Gel | Up to 100,000 cP | NEMA 11 3:1 |

30cc | Polypropylene | Up to 50°C | Optional | Disposable Reservoir Normal Torque |

| RSD-30-BD |

|

Liquid, Gel | Up to 100,000 cP | NEMA 11 3:1 |

30cc | Polypropylene | -5°C to 80°C | Optional | Disposable Reservoir Normal Torque |

| EMO |

|

Liquid, Gel, Paste | Up to 300,000 cP | NEMA 11 19:1, 27:1 |

25cc | Aluminum | Ambient | Optional | Reusable Reservoir Normal Torque |

| VOL |

|

Liquid, Gel, Paste | Up to 300,000 cP | NEMA 11 51:1 |

25cc | Aluminum | Up to 90°C | Optional | Reusable Reservoir Normal Torque |

| KR2 |

|

Paste, Clay, Hot Glue | Up to 1,000,000 cP | NEMA 11 100:1 |

15cc | Stainless | Up to 180°C | Optional | Reusable Reservoir High Torque |

| TAM |

|

Paste, Clay, Hot Glue | Up to 1,000,000 cP | NEMA 11 100:1 |

15cc | Stainless | Up to 270°C | Optional | Reusable Reservoir High Torque |

| UVP-365nm |

|

Photoinitiators | n/a | n/a | n/a | n/a | n/a | 365nm | Focusable |

| UVP-405nm |

|

Photoinitiators | n/a | n/a | n/a | n/a | n/a | 405nm | Focusable |

| UVP-450nm |

|

Photoinitiators | n/a | n/a | n/a | n/a | n/a | 450nm | Focusable |

| Lasers, 808nm |

|

Dark, Opaque | Laser | n/a | n/a | n/a | n/a | n/a | 5w, 808nm |

| Lasers, 450nm |

|

Opaque | Laser | n/a | n/a | n/a | n/a | n/a | 6w, 450nm |

| Lasers, 10μm | Translucent | Laser | n/a | n/a | n/a | n/a | n/a | 40w, 10μm | |

| ST1 |

|

Waxes, Plastics LIGHT Drilling |

Spindle Tool | n/a | 12VDC, 4A, 40W | n/a | n/a | n/a | 5,000 (with no load) |

| ST3 |

|

Plastics, Brass LIGHT Machining |

Spindle Tool | n/a | 48VDC, 8.3A, 400W | n/a | n/a | n/a | 12,000 (with no load) |

Note, for crosslinking heads, just see the standard heads and add the UV LED mechanism.

For details about Filament-based print heads, please visit our Filament_Heads page.

For details about Reservoir-based print heads, please visit our Reservoir_Heads page.

Nordson and ViscoTec Heads

Some customers have requested that we configure our equipment in such a way that heads from other companies like the Nordson Ultimus V heads or one of the Viscotec Vipro heads. Yes, Hyrel equipment can accommodate these and other print heads with just a little custom code and a special tool holder. Please contact us if you have any questions at all.

Other Accessories

Accessories other than print heads are available, some of which take a tool position.

For more details about Lasers, see the Lasers page.

For more details about Spindle Tools and other accessories, see the Other_accessories page.