Difference between revisions of "Hydra 16A"

| Line 97: | Line 97: | ||

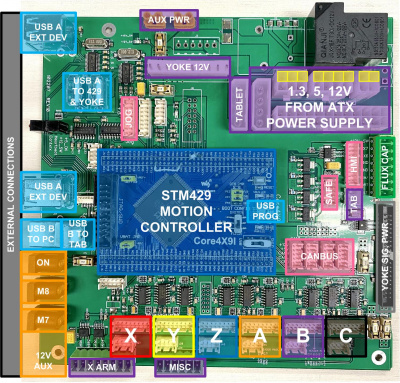

The Front Panel has the Tablet Interface Board (with STM429 Motion Controller) and External Ports. | The Front Panel has the Tablet Interface Board (with STM429 Motion Controller) and External Ports. | ||

[[File: | [[File:16A_TIB_2021_L.jpg|400px]] | ||

==== Rear Panel ==== | ==== Rear Panel ==== | ||

Revision as of 13:50, 29 January 2021

The Hydra 16A is our large format machine. Introduced in 2016, it features hard resolution (with encoder feedback) of 20 microns in the X and Y, and 0.8 microns in the Z in standard mode. In microstepping mode, we can achieve soft resolution of 4 microns in the X and Y. It comes standard with two tool positions, but can take additional yokes to handle more.

The base model has a range of 250mm in the Z, and can be equipped with the following (one is required):

- Bed, Standard, Warm: 400x300mm, 120C

- Bed, Standard, Hot: 400x300mm, 200C

- Bed, Large, Warm: 600x400mm, 120C

- Bed, Large, Hot: 600x444mm, 200C

In addition to the options available on most Hyrel printers, the Hydra 16A can also be equipped with:

- The 40 Watt CO2 laser (~10,000nm wavelength)

- The Pick-and-Place head with component tray

- The Three-Phase Spindle Tool for light machining operations

Most technical specifications are detailed in the comparison chart on the main page.

Adjustments

- Speed of travel (at slicing or in g-code editor)

- Layer thickness (at slicing)

- Volume of flow per unit distance (at slicing or in g-code editor)

- Extruder temperature (at slicing, in g-code editor, or manually during build) (MK-1, VOL-25)

- Cooling Fan speed (at slicing, in g-code editor, or manually during build (MK-1, QS-1)

- HotBed Temperature (at slicing, in g-code editor, or manually during build)

Or, is tabular better?

| Metric | Units | During Slicing | In G-Code Editor | GUI During Build |

|---|---|---|---|---|

| Speed of Travel | mm/min | yes | yes | no |

| Layer Thickness | mm | yes | no | no |

| Flow Rate | nL/sec | yes | yes | yes |

| Extruder Temperature | °C | yes | yes | yes |

| Fan Speed | % of max | yes | yes | yes |

| HotBed | °C | yes | yes | yes |

Controls

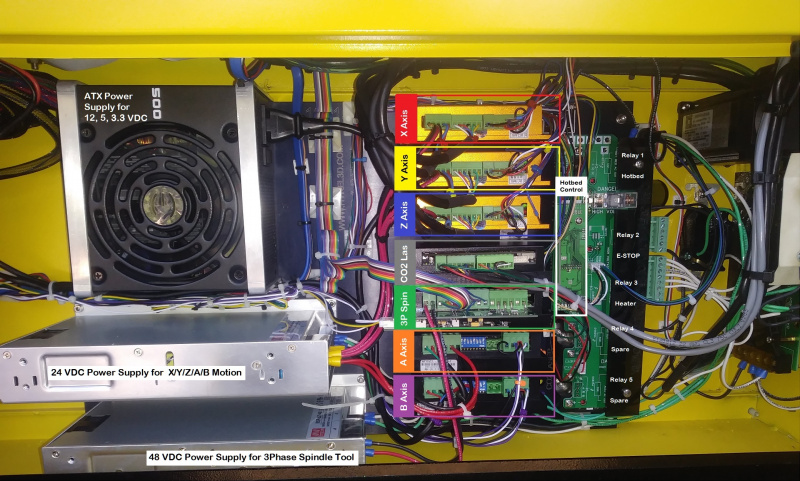

Here is an explanation of the electronics of the 16A; click any image to enlarge:

Main Panel

The Main Panel has the Power Supplies, Controllers, Encoders, and Relays.

- The Left Side:

- The ATX Power Supply provides 3.3, 5, and 12 VDC power to the processor, lights, and most heads loaded on the yoke.

- The 24 VDC Power Supply provides 24 VDC power to the motion motors - X, Y, Z, A, and B.

- The 48 VDC Power Supply provides 48 VDC power to the 3-phase spindle tool.

- The Center:

- The X Axis Encoder controls motion and monitors for errors in this axis.

- The Y Axis Encoder controls motion and monitors for errors in this axis.

- The Z Axis Encoder controls motion and monitors for errors in this axis.

- The optional CO2 Laser Driver controls the CO2 Laser.

- The optional 3-Phase Spindle Driver controls the 3-Phase Spindle Tool.

- The optional A Axis Encoder controls motion and monitors for errors in this axis.

- The optional B Axis Encoder controls motion and monitors for errors in this axis.

- The Right Side:

- The Hotbed Controller controls the heated or chilled build platform and the emergency stop.

- The Relays control power to:

- The Hotbed (or Coldbed)

- The Emergency Stop

- The Chamber Heater

- (spare)

- (spare)

Front Panel

The Front Panel has the Tablet Interface Board (with STM429 Motion Controller) and External Ports.

Rear Panel

The Rear Panel has the Power Entry.