Difference between revisions of "Hydra 16A"

Jump to navigation

Jump to search

| Line 47: | Line 47: | ||

|} | |} | ||

== Controls == | |||

Here is an explanation of the electronics of the 16A; click any image to enlarge: | Here is an explanation of the electronics of the 16A; click any image to enlarge: | ||

=== Main Panel === | |||

The Main Panel has the Power Supplies, Controllers, Encoders, and Relays. | The Main Panel has the Power Supplies, Controllers, Encoders, and Relays. | ||

| Line 78: | Line 78: | ||

*** (spare) | *** (spare) | ||

=== Front Panel === | |||

The Front Panel has the Tablet Interface Board (with STM429 Motion Controller) and External Ports. | The Front Panel has the Tablet Interface Board (with STM429 Motion Controller) and External Ports. | ||

[[File:16A_TIB_2021_L.jpg|400px]] | [[File:16A_TIB_2021_L.jpg|400px]] | ||

Revision as of 17:12, 29 January 2021

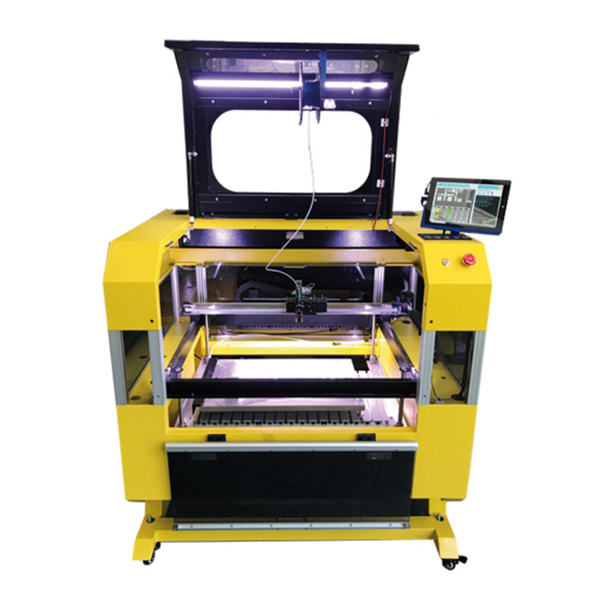

The Hydra 16A is our large format machine.

History

- The Hydra 16A was introduced in 2015.

Technical Data

Technical specifications and accessory compatibility for printers currently shipping are detailed in the comparison chart on the Printer Overview page.

Adjustments

| Metric | Units | During Slicing | In G-Code Editor | GUI During Build |

|---|---|---|---|---|

| Speed of Travel | mm/min | yes | yes | no |

| Layer Thickness | mm | yes | no | no |

| Flow Rate | nL/sec | yes | yes | yes |

| Extruder Temperature | °C | yes | yes | yes |

| Fan Speed | % of max | yes | yes | yes |

| HotBed | °C | yes | yes | yes |

Controls

Here is an explanation of the electronics of the 16A; click any image to enlarge:

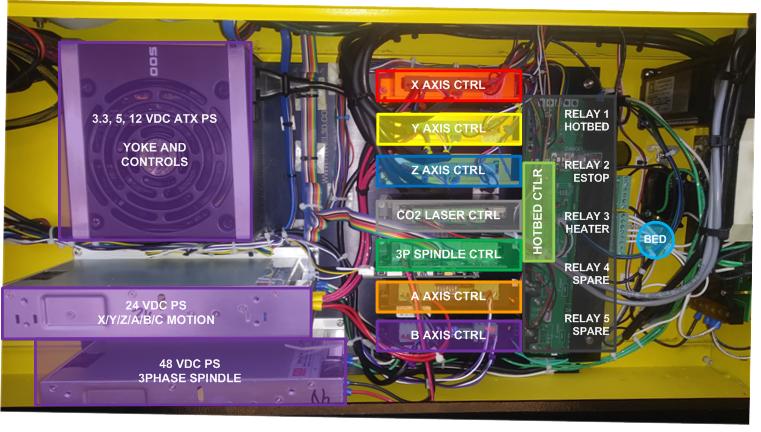

Main Panel

The Main Panel has the Power Supplies, Controllers, Encoders, and Relays.

- The Left Side:

- The ATX Power Supply provides 3.3, 5, and 12 VDC power to the processor, lights, and most heads loaded on the yoke.

- The 24 VDC Power Supply provides 24 VDC power to the motion motors - X, Y, Z, A, and B.

- The 48 VDC Power Supply provides 48 VDC power to the 3-phase spindle tool.

- The Center:

- The X Axis Encoder controls motion and monitors for errors in this axis.

- The Y Axis Encoder controls motion and monitors for errors in this axis.

- The Z Axis Encoder controls motion and monitors for errors in this axis.

- The optional CO2 Laser Driver controls the CO2 Laser.

- The optional 3-Phase Spindle Driver controls the 3-Phase Spindle Tool.

- The optional A Axis Encoder controls motion and monitors for errors in this axis.

- The optional B Axis Encoder controls motion and monitors for errors in this axis.

- The Right Side:

- The Hotbed Controller controls the heated or chilled build platform and the emergency stop.

- The Relays control power to:

- The Hotbed (or Coldbed)

- The Emergency Stop

- The Chamber Heater

- (spare)

- (spare)

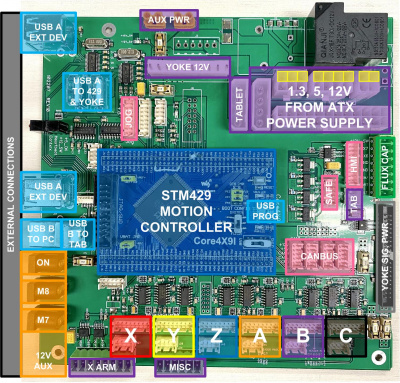

Front Panel

The Front Panel has the Tablet Interface Board (with STM429 Motion Controller) and External Ports.