Difference between revisions of "KR2"

| (2 intermediate revisions by the same user not shown) | |||

| Line 5: | Line 5: | ||

|} | |} | ||

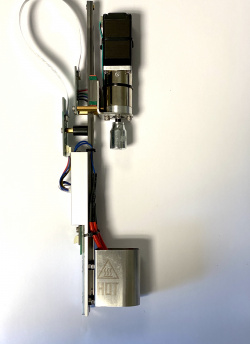

The KR2 | The KR2 is our 15cc print head for high viscosity emulsions which print at up to 180°C, with our improved reservoir/plunger system. | ||

[[File:KR2.jpg|250px|left|KR2]] | [[File:KR2.jpg|250px|left|KR2]] | ||

| Line 19: | Line 17: | ||

</div> | </div> | ||

Additionally, the KR2 | Additionally, the KR2's temperature range allows it to function as an EMO or a VOL. | ||

== Description == | == Description == | ||

| Line 25: | Line 23: | ||

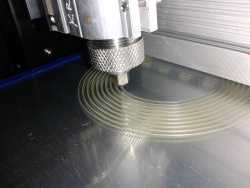

[[File:KR2_print.jpg|250px|right|KR2 Printing 3M 3796]] | [[File:KR2_print.jpg|250px|right|KR2 Printing 3M 3796]] | ||

The improved reservoir/plunger system consists of a custom machined reservoir, a dual-gasketed plunger, and a ball screw in place of the threaded rod. These improvements were made to surmount the issue of high temperature, high viscosity material leaking past the single gasket of the KRA; most users will not encounter this situation. As an option to reduce wasted volume, a conical plunger is available. | |||

== UV Crosslinking == | |||

All of our reservoir-based heads can take a [[UV_Array|UV Array]], mounted around the nozzle, or a [[UVP|UV Pen]], mounted in another tool position. | |||

The [[UV_Array|UV Arrays]] are lower power, and available in 280, 310, 365, 405, or 450 nm. | |||

The | The [[UVP|UV Pens]] are higher power, and available in 365, 405, or 450nm. | ||

== Loading the Head onto the Printer == | == Loading the Head onto the Printer == | ||

| Line 66: | Line 68: | ||

== Maintenance == | == Maintenance == | ||

While cleaning your print media from the tube and nozzle after every print is important, very little other maintenance is required on this head. | While cleaning your print media from the tube and nozzle after every print is important, very little other maintenance is required on this head. We DO recommend lubricating the screw as needed, with light grease, petroleum jelly, "3 in 1", sewing, or other light machine oil. | ||

Latest revision as of 17:07, 15 April 2021

The KR2 is our 15cc print head for high viscosity emulsions which print at up to 180°C, with our improved reservoir/plunger system.

This includes the following materials:

- Emulsions

- Resins

- Hot Glues, including 3M 3796

Additionally, the KR2's temperature range allows it to function as an EMO or a VOL.

Description

The improved reservoir/plunger system consists of a custom machined reservoir, a dual-gasketed plunger, and a ball screw in place of the threaded rod. These improvements were made to surmount the issue of high temperature, high viscosity material leaking past the single gasket of the KRA; most users will not encounter this situation. As an option to reduce wasted volume, a conical plunger is available.

UV Crosslinking

All of our reservoir-based heads can take a UV Array, mounted around the nozzle, or a UV Pen, mounted in another tool position.

The UV Arrays are lower power, and available in 280, 310, 365, 405, or 450 nm.

The UV Pens are higher power, and available in 365, 405, or 450nm.

Loading the Head onto the Printer

As with all Hyrel heads, the following process should be followed:

- Start with a level bed and Repetrel running and connected to the printer.

- Load the gibs on the Head into the gib slots on the Yoke from above and slide the head down into place; the last mm of travel should be done gently, ensuring that the electrical connector seats properly (firmly and completely) into the receiving connector.

- Ensure the LEDs on the print head are flashing - this means the Head is communicating with the Motion Controller.

- Tighten the thumbscrew in the rear, to prevent the head from moving relative to the Yoke.

- If the Head doesn't show up in Repetrel, press and release the RESET button on the front of the printer.

- Once the Head is shown in repetrel, proceed to setting your Z-Zero position.

Loading material into the Head

Loading:

- Care should be taken to avoid air pockets, as this will introduce delay when starting and stopping material flow.

Unloading:

- Unloading is the same process as loading, only in reverse. Tubes and nozzles should be cleaned thoroughly after use.

Default Parameters

Default settings for the KR2 are shown on the Cold_and_Warm_Flow page.

Adjustments

The only adjustments needed should be changes to the PRIME and UNPRIME settings, and will have to be dialed in based on how viscous and compressible your material is, and how narrow a nozzle or luer tip you are using.. In dialing in new settings, I usually double or half the settings for both STEPS and TIME, then make another print and reassess.

Firmware

Please see the Downloads page for the current firmware for your heads and your version of Repetrel.

Maintenance

While cleaning your print media from the tube and nozzle after every print is important, very little other maintenance is required on this head. We DO recommend lubricating the screw as needed, with light grease, petroleum jelly, "3 in 1", sewing, or other light machine oil.