Difference between revisions of "Reservoir Heads"

| (40 intermediate revisions by 2 users not shown) | |||

| Line 6: | Line 6: | ||

Reservoir Heads is how we print (also known as Direct Ink Writing or Robocasting) with fluid or emulsified (non-filament-based) materials which are deposited at, above, or below room temperature, with or without UV Crosslinking. | Reservoir Heads is how we print (also known as Direct Ink Writing or Robocasting) with fluid or emulsified (non-filament-based) materials which are deposited at, above, or below room temperature, with or without UV Crosslinking. | ||

== Nordson and ViscoTec Heads == | |||

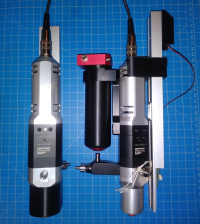

[[File:Nordson_viscotec_vipro_medium.jpg|left|200px|caption]] Some customers have requested that we configure our equipment in such a way that heads from other companies like the [https://www.nordson.com/en/divisions/efd/products/fluid-dispensing-systems/ultimus-v-high-precision-dispenser '''Nordson Ultimus V heads'''] or one of the [https://www.viscotec.de/en/products/3d-print-heads/ '''Viscotec Vipro heads''']. | |||

Yes, Hyrel equipment can accommodate these and other print heads with just a little custom code and a special tool holder. Please contact us if you have any questions at all. | |||

Click image for a larger image. | |||

==Materials for Reservoir Heads== | ==Materials for Reservoir Heads== | ||

| Line 58: | Line 66: | ||

<gallery> | <gallery> | ||

File:EMO-25.png|[[EMO]]-25 | File:EMO-25.png|[[EMO]]-25 | ||

File:COD-25.png|[[ | File:COD-25.png|[[EMO]]-25 with UV array | ||

File:SDS-30.png|[[SDS]]-5, [[SDS]]-10,<br>[[SDS]]-30, [[SDS]]-60 | File:SDS-30.png|[[SDS]]-5, [[SDS]]-10,<br>[[SDS]]-30, [[SDS]]-60 | ||

File:CSD-60.png|[[ | File:CSD-60.png|[[SDS]]-5, [[SDS]]-10,<br>[[SDS]]-30, [[SDS]]-60 with UV array | ||

SMH-2 Static Mixing Head | File:SMH2.jpg | [[SMH]]-2 Static Mixing Head | ||

</gallery> | </gallery> | ||

| Line 68: | Line 76: | ||

<gallery> | <gallery> | ||

File:VOL-25.png|[[VOL]]-25 | File:VOL-25.png|[[VOL]]-25 | ||

File:VCD-25.png|[[VOL]]-25 with | File:VCD-25.png|[[VOL]]-25 with UV array | ||

File:KRA-15.png|[[KRA]]-15 | File:KRA-15.png|[[KRA]]-15 | ||

File:KCD-15.png|[[KRA]]-15 with | File:KCD-15.png|[[KRA]]-15 with UV array | ||

</gallery> | </gallery> | ||

| Line 106: | Line 114: | ||

:[[VOL]]: Volcano: Heated (up to 100°C) Emulsifiables - Low to Medium Viscosity | :[[VOL]]: Volcano: Heated (up to 100°C) Emulsifiables - Low to Medium Viscosity | ||

:[[KR2]]: Krakatoa v2: a more robust KRA head with a double gasketed plunger hotter, more viscous Emulsifiables - Very High Viscosity | :[[KR2]]: Krakatoa v2: a more robust KRA head with a double gasketed plunger hotter, more viscous Emulsifiables - Very High Viscosity | ||

:[[TAM]]: Tambora: Heated (up to | :[[TAM]]: Tambora: Heated (up to 270°C) Emulsifiables - High Viscosity | ||

:[[SDS]]: Syringe Dispensing System (uses disposable plastic syringes at room temperature) - Low Viscosity | :[[SDS]]: Syringe Dispensing System (uses disposable plastic syringes at room temperature) - Low Viscosity | ||

:[[HSD]]: Heated (formerly Volcanic) Syringe Dispensing System - Low to Medium Viscosity | :[[HSD]]: Heated (formerly Volcanic) Syringe Dispensing System - Low to Medium Viscosity | ||

| Line 120: | Line 128: | ||

Firmware information is listed [[Firmware|on our Firmware page]]. | Firmware information is listed [[Firmware|on our Firmware page]]. | ||

== Reservoirs for Reservoir Heads == | |||

We've used different reservoirs over the years. Here are the details. | |||

=== Metal Reservoirs === | |||

{| border="1" class="wikitable" style="text-align: center; width: 80%;" | |||

|+ Metal Reservoirs | |||

! style="width: 10%;" | Tube Material | |||

! style="width: 10%;" | Plunger <br> O-Rings | |||

! style="width: 10%;" | Nominal <br> Volume | |||

! style="width: 10%;" | ID <br> mm | |||

! style="width: 10%;" | OD <br> mm | |||

! style="width: 10%;" | Default <br> Heads | |||

! style="width: 10%;" | Also <br> Compatible | |||

! style="width: 20%;" | Notes | |||

|- | |||

| Aluminum || 1 || 25 cc || 16.9 mm || 20.2 mm || EMO, VOL || EMO-XT || Modified "Makin" | |||

|- | |||

| Stainless || 1 || 15 cc || 17.7 mm || 20 mm || KRA* || none || Modified "Makin" | |||

|- | |||

| Stainless || 1 || 25 cc || 17.7 mm || 20 mm || none || EMO, VOL, EMO-XT || Modified "Makin" | |||

|- | |||

| Stainless || 2 || 15 cc || 18 mm || 20 mm || KR2, TAM, EMO-XT || none || Custom | |||

|- | |||

|} | |||

=== Plastic Reservoirs === | |||

{| border="1" class="wikitable" style="text-align: center; width: 80%;" | |||

|+ Plastic Reservoirs | |||

! style="width: 20%;" | Default <br> Heads | |||

! style="width: 10%;" | Tube Material | |||

! style="width: 20%;" | Manufacturer | |||

! style="width: 10%;" | Part <br> Number | |||

! style="width: 10%;" | Nominal <br> Volume | |||

! style="width: 10%;" | Notes | |||

! style="width: 20%;" | Hyrel Part | |||

! style="width: 10%;" | Quantity | |||

|- | |||

| SDS-1 || Polypropylene || MHC Easy-Touch || 802010 || 1 cc || none || AN.SYR-01/100-MHC || 100 | |||

|- | |||

| SDS-5 || Polypropylene || BD || 309646 || 5 cc || none || AN.SYR-05/125-BD || 125 | |||

|- | |||

| SDS-10 || Polypropylene || BD || 309604 || 10 cc || none || AN.SYR-10/100-BD || 100 | |||

|- | |||

| SDS-30<br>SDS-30XT || Polypropylene || BD || 302832 || 30 cc || none || AN.SYR-30/54-BD || 54 | |||

|- | |||

| SDS-60<br>SDS-60XT || Polypropylene || BD || 309653 || 60 cc || none || AN.SYR-60/40-BD|| 40 | |||

|- | |||

| SDS-150XT || Polypropylene || - || - || 150 cc || none || AN.SYR-150/10|| 10 | |||

|- | |||

| HSD-10 || Polyamide || Ardes* || || 10 cc || *modified || AN.SYR-10-Ardes || 1 | |||

|- | |||

|} | |||

== Settings for Reservoir Heads == | == Settings for Reservoir Heads == | ||

| Line 137: | Line 201: | ||

! style="width: 10%" | [[VOL]]<br>51:1 Ratio | ! style="width: 10%" | [[VOL]]<br>51:1 Ratio | ||

! style="width: 10%" | EMO-XT, [[KR2]], [[TAM]]<br>100:1 | ! style="width: 10%" | EMO-XT, [[KR2]], [[TAM]]<br>100:1 | ||

! style="width: 10%" | | ! style="width: 10%" | [[KR2]]-ST <br> Super Torque | ||

! style="width: 10%" | EMO-300XT<br> | ! style="width: 10%" | EMO-300XT <br> eXtra Torque | ||

|- | |- | ||

!colspan="7"| Material | !colspan="7"| Material | ||

| Line 174: | Line 238: | ||

! Print Temp | ! Print Temp | ||

| 0 | | 0 | ||

| 35 | | 0, 35 | ||

| 35 | | 35 | ||

| (varies) | | (varies) | ||

| Line 203: | Line 267: | ||

|- | |- | ||

! rowspan="2" | Pulses / µL | ! rowspan="2" | Pulses / µL | ||

| | | '''271.9''' | ||

| 517 | | 517 | ||

| | | '''1297''' | ||

| ? | | ? | ||

| ? | | ? | ||

| Line 303: | Line 367: | ||

|- | |- | ||

! RTD Type | ! RTD Type | ||

| | | 1k_PRTD | ||

| | | 1k_PRTD | ||

| | | 1k_PRTD | ||

| | | 1k_PRTD | ||

| | | 1k_PRTD | ||

|- | |- | ||

! Plot Settings | ! Plot Settings | ||

| Line 342: | Line 406: | ||

| 1,500 | | 1,500 | ||

| 1,500 | | 1,500 | ||

| | | 10,000 | ||

| ? | | ? | ||

| ? | | ? | ||

|- | |- | ||

! style="width: 10%" | Settings | ! style="width: 10%" | Settings | ||

! style="width: 10%" | [[EMO]]<br>27:1 Ratio | ! style="width: 10%" | [[EMO]], [[VOL]]<br>27:1 Ratio | ||

! style="width: 10%" | [[VOL]]<br>51:1 Ratio | ! style="width: 10%" | [[VOL]]<br>51:1 Ratio | ||

! style="width: 10%" | EMO-XT, [[KR2]], [[TAM]]<br>100:1 | ! style="width: 10%" | EMO-XT, [[KR2]], [[TAM]]<br>100:1 | ||

! style="width: 10%" | | ! style="width: 10%" | [[KR2]]-ST <br> Super Torque | ||

! style="width: 10%" | EMO-300XT<br> | ! style="width: 10%" | EMO-300XT <br> eXtra Torque | ||

|- | |- | ||

|} | |} | ||

| Line 361: | Line 425: | ||

|- | |- | ||

! style="width: 10%" | Settings | ! style="width: 10%" | Settings | ||

! style="width: 10%" | [[SDS]] | ! style="width: 10%" | [[SDS]] 1 ET | ||

! style="width: 10%" | [[SDS]] | ! style="width: 10%" | [[SDS]] 5 | ||

! style="width: 10%" | [[SDS]] | ! style="width: 10%" | [[SDS]] 10 | ||

! style="width: 15%" | [[SDS]]/[[HSD]]/[[RSD]] | ! style="width: 15%" | [[SDS]]/[[HSD]]/[[RSD]] 30 | ||

! style="width: 10%" | [[SDS]] | ! style="width: 10%" | [[SDS]] 60 | ||

|- | |- | ||

!colspan="11"| Material | !colspan="11"| Material | ||

| Line 430: | Line 494: | ||

|- | |- | ||

! rowspan="2" | Pulses / µL | ! rowspan="2" | Pulses / µL | ||

| | | 270 | ||

| '''87.3''' | | '''87.3''' | ||

| '''58.7''' | | '''58.7''' | ||

| Line 448: | Line 512: | ||

|- | |- | ||

! Steps | ! Steps | ||

| | | 3000 | ||

| 1500 | | 1500 | ||

| 3000 | | 3000 | ||

| Line 462: | Line 526: | ||

|- | |- | ||

! Dwell Time (ms) | ! Dwell Time (ms) | ||

| | | 300 | ||

| 150 | | 150 | ||

| 300 | | 300 | ||

| | | 225 | ||

| | | 150 | ||

|- | |- | ||

! colspan="11"| Unprime | ! colspan="11"| Unprime | ||

|- | |- | ||

! Steps | ! Steps | ||

| | | 3000 | ||

| 1500 | | 1500 | ||

| 3000 | | 3000 | ||

| Line 485: | Line 549: | ||

|- | |- | ||

! Dwell Time | ! Dwell Time | ||

| - | | -300 | ||

| -150 | | -150 | ||

| -300 | | -300 | ||

| Line 524: | Line 588: | ||

|- | |- | ||

! Model | ! Model | ||

| SDS | | SDS | ||

| SDS-5 | | SDS-5 | ||

| SDS-10 | | SDS-10 | ||

| Line 541: | Line 605: | ||

| None | | None | ||

| None | | None | ||

| None / | | None / 1k_PRTD / 1k_PRTD | ||

| None | | None | ||

|- | |- | ||

| Line 582: | Line 646: | ||

|- | |- | ||

! style="width: 10%" | Settings | ! style="width: 10%" | Settings | ||

! style="width: 10%" | [[SDS]] | ! style="width: 10%" | [[SDS]] 1 ET | ||

! style="width: 10%" | [[SDS]] | ! style="width: 10%" | [[SDS]] 5 | ||

! style="width: 10%" | [[SDS]] | ! style="width: 10%" | [[SDS]] 10 | ||

! style="width: 15%" | [[SDS]]/[[HSD]]/[[RSD]] | ! style="width: 15%" | [[SDS]]/[[HSD]]/[[RSD]] 30 | ||

! style="width: 10%" | [[SDS]] | ! style="width: 10%" | [[SDS]] 60 | ||

|- | |- | ||

| Line 597: | Line 661: | ||

! style="width: 10%" | Settings | ! style="width: 10%" | Settings | ||

! style="width: 10%" | [[HSD-10-Ardes]] | ! style="width: 10%" | [[HSD-10-Ardes]] | ||

! style="width: 10%" | [[SDS | ! style="width: 10%" | [[SDS]]-30-XT | ||

! style="width: 10%" | [[SDS | ! style="width: 10%" | [[SDS]]-60-XT | ||

! style="width: 10%" | | ! style="width: 10%" | [[SDS]]-150-XT | ||

! style="width: 10%" | DSD-50 | ! style="width: 10%" | [[DSD-50]] | ||

|- | |- | ||

!colspan="6"| Material | !colspan="6"| Material | ||

| Line 656: | Line 720: | ||

|- | |- | ||

! Maximum | ! Maximum | ||

| | | 75 | ||

| 0 | | 0 | ||

| 0 | | 0 | ||

| Line 697: | Line 761: | ||

|- | |- | ||

! Dwell Time (ms) | ! Dwell Time (ms) | ||

| 900 | | 900 | ||

| 115 | |||

| 150 | |||

| 150 | |||

| 1 | |||

|- | |- | ||

! colspan="6"| Unprime | ! colspan="6"| Unprime | ||

| Line 811: | Line 875: | ||

! style="width: 10%" | Settings | ! style="width: 10%" | Settings | ||

! style="width: 10%" | [[HSD-10-Ardes]] | ! style="width: 10%" | [[HSD-10-Ardes]] | ||

! style="width: 10%" | [[SDS | ! style="width: 10%" | [[SDS]]-30-XT | ||

! style="width: 10%" | [[SDS | ! style="width: 10%" | [[SDS]]-60-XT | ||

! style="width: 10%" | | ! style="width: 10%" | [[SDS]]-150-XT | ||

! style="width: 10%" | DSD-50 | ! style="width: 10%" | DSD-50 | ||

|- | |- | ||

|} | |} | ||

Latest revision as of 14:19, 24 June 2021

Reservoir Heads is how we print (also known as Direct Ink Writing or Robocasting) with fluid or emulsified (non-filament-based) materials which are deposited at, above, or below room temperature, with or without UV Crosslinking.

Nordson and ViscoTec Heads

Some customers have requested that we configure our equipment in such a way that heads from other companies like the Nordson Ultimus V heads or one of the Viscotec Vipro heads.

Yes, Hyrel equipment can accommodate these and other print heads with just a little custom code and a special tool holder. Please contact us if you have any questions at all.

Click image for a larger image.

Materials for Reservoir Heads

Reservoir Heads heads are for printing as follows:

- With pastes, gels, emulsifiables or waxes.

- At room or elevated temperatures.

- With or without UV Crosslining.

- With Hyrel Nozzles (1.5mm, 2mm) or Luer Tips.

The following materials can be printed from Cold Flow heads. Note that more viscous materials may not be suitable for plastic syringes or smaller luer tips.

- 3P Quick Cure Clay

- Adhesives

- Clay, Generic

- Epoxy, Two-part

- Fimo

- Glue

- Kato

- Metal Clay, including Precious Metal Clay (PMC)

- Modeling Clay

- PEG PolyEthylene Glycol

- Porcelain

- Plasticine

- Play-Doh

- Resins

- RTV Silicone

- Sculpey

- Sugru

The following materials can be printed from Warm Flow heads. Note that more viscous materials may not be suitable for plastic syringes or smaller luer tips, or may print more easily at higher temperatures.

Reservoir Heads

Ambient or sub-ambient deposition is available through the following Reservoir-based heads:

Heated deposition is available through the following Reservoir-based heads:

Overview of the EMO Heads

Overview of the EMO Heads Overview of the SDS Heads

Overview of the SDS Heads Overview of the VOL Heads

Overview of the VOL Heads Overview of the KRA Heads

Overview of the KRA Heads Overview of the SMH-2 Head

Overview of the SMH-2 Head- Please see our Manuals as well.

| Temperature > | 20°C < Ambient | Ambient | Up to 50°C | Up to 90°C | Up to 180°C | Up to 270°C |

|---|---|---|---|---|---|---|

| Crosslinking Optional |

RSD-30 | EMO-25 SDS-5, -10, SDS-30, -60 SMH-2 |

HSD-30 | HSD-10 VOL-25 |

KRA-15 KR2-15 |

TAM-15 |

Note, RSD-30 will take you about 20C below ambient.

So, what do these goofy designations actually stand for?

- EMO: Emulsifiables at Room Temperature - Low to Medium Viscosity

- COD: Emulsifiables T Room Temperature with Crosslink On Demand - Low to Medium Viscosity

- VOL: Volcano: Heated (up to 100°C) Emulsifiables - Low to Medium Viscosity

- KR2: Krakatoa v2: a more robust KRA head with a double gasketed plunger hotter, more viscous Emulsifiables - Very High Viscosity

- TAM: Tambora: Heated (up to 270°C) Emulsifiables - High Viscosity

- SDS: Syringe Dispensing System (uses disposable plastic syringes at room temperature) - Low Viscosity

- HSD: Heated (formerly Volcanic) Syringe Dispensing System - Low to Medium Viscosity

- RSD: Refrigerated Syringe Dispensing System - Low to Medium Viscosity

- DSD: Dual Syringe Dispenser, dispensing two-part mixtures at a fixed ratio - Low to Medium Viscosity

- SMH: Static Mixing Head, blending your ratio of material through a baffled nozzle - Low to Medium Viscosity

Research Papers Citing Hyrel Reservoir Heads

These are now listed by year here.

Firmware Versions for Reservoir Heads

Firmware information is listed on our Firmware page.

Reservoirs for Reservoir Heads

We've used different reservoirs over the years. Here are the details.

Metal Reservoirs

| Tube Material | Plunger O-Rings |

Nominal Volume |

ID mm |

OD mm |

Default Heads |

Also Compatible |

Notes |

|---|---|---|---|---|---|---|---|

| Aluminum | 1 | 25 cc | 16.9 mm | 20.2 mm | EMO, VOL | EMO-XT | Modified "Makin" |

| Stainless | 1 | 15 cc | 17.7 mm | 20 mm | KRA* | none | Modified "Makin" |

| Stainless | 1 | 25 cc | 17.7 mm | 20 mm | none | EMO, VOL, EMO-XT | Modified "Makin" |

| Stainless | 2 | 15 cc | 18 mm | 20 mm | KR2, TAM, EMO-XT | none | Custom |

Plastic Reservoirs

| Default Heads |

Tube Material | Manufacturer | Part Number |

Nominal Volume |

Notes | Hyrel Part | Quantity |

|---|---|---|---|---|---|---|---|

| SDS-1 | Polypropylene | MHC Easy-Touch | 802010 | 1 cc | none | AN.SYR-01/100-MHC | 100 |

| SDS-5 | Polypropylene | BD | 309646 | 5 cc | none | AN.SYR-05/125-BD | 125 |

| SDS-10 | Polypropylene | BD | 309604 | 10 cc | none | AN.SYR-10/100-BD | 100 |

| SDS-30 SDS-30XT |

Polypropylene | BD | 302832 | 30 cc | none | AN.SYR-30/54-BD | 54 |

| SDS-60 SDS-60XT |

Polypropylene | BD | 309653 | 60 cc | none | AN.SYR-60/40-BD | 40 |

| SDS-150XT | Polypropylene | - | - | 150 cc | none | AN.SYR-150/10 | 10 |

| HSD-10 | Polyamide | Ardes* | 10 cc | *modified | AN.SYR-10-Ardes | 1 |

Settings for Reservoir Heads

All printers and heads shipping after 1 Jan 2020 have shipped with some release of version 4, and these values are shown below.

Older settings are listed here.

Some settings for the EMO-Type heads (like temperature, prime/unprime values) will vary, depending on what material you are printing with. Nozzle diameter should accurately reflect what nozzle you have loaded (1.6mm is default) AND what path width you sliced for. Temperature commands will be ignored by heads with no temperature control. Having said that, below are our default shipping settings:

METAL Reservoir Heads

| Settings | EMO, VOL 27:1 Ratio |

VOL 51:1 Ratio |

EMO-XT, KR2, TAM 100:1 |

KR2-ST Super Torque |

EMO-300XT eXtra Torque | |

|---|---|---|---|---|---|---|

| Material | ||||||

| Type | Custom | Custom | Custom | Custom | Custom | |

| Color | (any) | (any) | (any) | (any) | (any) | |

| Nozzle | 1.600 | 1.600 | 1.600 | 1.600 | 1.600 | |

| Layer | (any) | (any) | (any) | (any) | (any) | |

| Temp Info | ||||||

| Print Temp | 0 | 0, 35 | 35 | (varies) | 0 | |

| Power Factor | 100 | 100 | 100 | 100 | 100 | |

| Minimum | 0 | 0 | 0 | 0 | 0 | |

| Maximum | 0 | 90 | 0 / 180 / 270 | 0 | 0 | |

| Overrides | ||||||

| Pulses / µL | 271.9 | 517 | 1297 | ? | ? | |

| Note: Values above in BOLD have been validated through multiple sample testing, July 2020. | ||||||

| Multiplier | 1 | 1 | 1 | ? | ? | |

| Prime | ||||||

| Steps | 6000 | 1000 | 6000 | ? | ? | |

| Rate | 10,000 | 10,000 | 10,000 | ? | ? | |

| Dwell Time (ms) | 600 | 100 | 600 | ? | ||

| Unprime | ||||||

| Steps | 6000 | 1000 | 6000 | ? | ? | |

| Rate | 10,000 | 10,000 | 10,000 | ? | ? | |

| Dwell Time | -600 | -100 | -600 | ? | ? | |

| Offsets | ||||||

| X | 0,000 | 0,000 | 0,000 | 0,000 | 0,000 | |

| Y | 0,000 | 0,000 | 0,000 | 0,000 | 0,000 | |

| Z | 0,000 | 0,000 | 0,000 | 0,000 | 0,000 | |

| Head Info | ||||||

| Model | EMO-25 | VOL-25 | KR2-15 or TAM-15 | (varies) | EMO-300XT | |

| PCB Type | 4988/160J | 4988/160J | 4988/160J | 4988/160J | 4988/160J | |

| RTD Type | 1k_PRTD | 1k_PRTD | 1k_PRTD | 1k_PRTD | 1k_PRTD | |

| Plot Settings | (any) | (any) | (any) | (any) | (any) | |

| Motor Settings | ||||||

| Step Mode | 16th | 16th | 16th | 16th | ? | |

| Motor Current | Normal | Normal | Normal | Normal | ? | |

| Max Jog Rate | 5,000 | 10,000 | 15,000 | ? | ? | |

| Rot Speed | 1,500 | 1,500 | 10,000 | ? | ? | |

| Settings | EMO, VOL 27:1 Ratio |

VOL 51:1 Ratio |

EMO-XT, KR2, TAM 100:1 |

KR2-ST Super Torque |

EMO-300XT eXtra Torque | |

PLASTIC Reservoir Heads: Table 1

| Settings | SDS 1 ET | SDS 5 | SDS 10 | SDS/HSD/RSD 30 | SDS 60 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | ||||||||||

| Type | Custom | Custom | Custom | Custom | Custom | |||||

| Color | (any) | (any) | (any) | (any) | (any) | |||||

| Nozzle | 1.600 | 1.600 | 1.600 | 1.600 | 1.600 | |||||

| Layer | (any) | (any) | (any) | (any) | (any) | |||||

| Temp Info | ||||||||||

| Print Temp | 0 | 0 | 0 | 0 | 0 | |||||

| Power Factor | 100 | 100 | 100 | 100 | 100 | |||||

| Minimum | 0 | 0 | 0 | 0 | 0 | |||||

| Maximum | 0 | 0 | 0 | 0 / 75 / -10 | 0 | |||||

| Overrides | ||||||||||

| Pulses / µL | 270 | 87.3 | 58.7 | 26.8 | 17.4 | |||||

| Note: Values above in BOLD have been validated through multiple sample testing, July 2020. | ||||||||||

| Multiplier | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | |||||

| Prime | ||||||||||

| Steps | 3000 | 1500 | 3000 | 2250 | 1500 | |||||

| Rate | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 | |||||

| Dwell Time (ms) | 300 | 150 | 300 | 225 | 150 | |||||

| Unprime | ||||||||||

| Steps | 3000 | 1500 | 3000 | 2250 | 1500 | |||||

| Rate | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 | |||||

| Dwell Time | -300 | -150 | -300 | -300 | -300 | |||||

| Offsets | ||||||||||

| Clone Head | Off | Off | Off | Off | Off | |||||

| X | 0,000 | 0,000 | 0,000 | 0,000 | 0,000 | |||||

| Y | 0,000 | 0,000 | 0,000 | 0,000 | 0,000 | |||||

| Z | 0,000 | 0,000 | 0,000 | 0,000 | 0,000 | |||||

| Head Info | ||||||||||

| Model | SDS | SDS-5 | SDS-10 | SDS-30 / HSD-30 / RSD-30 | SDS-60 | |||||

| PCB Type | 4988/160J | 4988/160J | 4988/160J | 4988/160J | 4988/160J | |||||

| RTD Type | None | None | None | None / 1k_PRTD / 1k_PRTD | None | |||||

| Plot Settings | (any) | (any) | (any) | (any) | (any) | |||||

| Motor Settings | ||||||||||

| Step Mode | 16th | 16th | 16th | 16th | 16th | |||||

| Motor Current | Normal | Normal | Normal | Normal | Normal | |||||

| Max Jog Rate | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 | |||||

| Rot Speed | 1500 | 1500 | 1500 | 1500 | 1500 | |||||

| Settings | SDS 1 ET | SDS 5 | SDS 10 | SDS/HSD/RSD 30 | SDS 60 | |||||

PLASTIC Reservoir Heads: Table 2

| Settings | HSD-10-Ardes | SDS-30-XT | SDS-60-XT | SDS-150-XT | DSD-50 |

|---|---|---|---|---|---|

| Material | |||||

| Type | Custom | Custom | Custom | Custom | Custom |

| Color | (any) | (any) | (any) | (any) | (any) |

| Nozzle | 1.600 | 1.600 | 1.600 | 1.600 | 4.00 |

| Layer | (any) | (any) | (any) | (any) | (any) |

| Temp Info | |||||

| Print Temp | 35 | 0 | 0 | 0 | 0 |

| Power Factor | 100 | 100 | 100 | 100 | 100 |

| Minimum | 0 | 0 | 0 | 0 | 0 |

| Maximum | 75 | 0 | 0 | 0 | 0 |

| Overrides | |||||

| Pulses / µL | 1800 | 86 | 29.1 | 12.8 | 20 |

| Note: Values above in BOLD have been validated through multiple sample testing, July 2020. | |||||

| Multiplier | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| Prime | |||||

| Steps | 9000 | 1125 | 1500 | 1500 | 1 |

| Rate | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 |

| Dwell Time (ms) | 900 | 115 | 150 | 150 | 1 |

| Unprime | |||||

| Steps | 9000 | 1125 | 1500 | 1500 | 1 |

| Rate | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 |

| Dwell Time | -900 | -300 | -300 | -300 | -100 |

| Offsets | |||||

| X | 0,000 | 0,000 | 0,000 | 0,000 | 0,000 |

| Y | 0,000 | 0,000 | 0,000 | 0,000 | 0,000 |

| Z | 0,000 | 0,000 | 0,000 | 0,000 | 0,000 |

| Head Info | |||||

| Model | (varies) | (varies) | (varies) | (varies) | (varies) |

| PCB Type | 4988/160J | 4988/160J | 4988/160J | 4988/160J | 4988/160J |

| RTD Type | 1k_PLAT_RTD | None | None | None | None |

| Plot Settings | (any) | (any) | (any) | (any) | (any) |

| Motor Settings | |||||

| Step Mode | 16th | 16th | 16th | 16th | 16th |

| Motor Current | Normal | Normal | Normal | Normal | Normal |

| Max Jog Rate | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 |

| Rot Speed | 7,500 | 1,500 | 1,500 | 1,500 | 1,500 |

| Settings | HSD-10-Ardes | SDS-30-XT | SDS-60-XT | SDS-150-XT | DSD-50 |