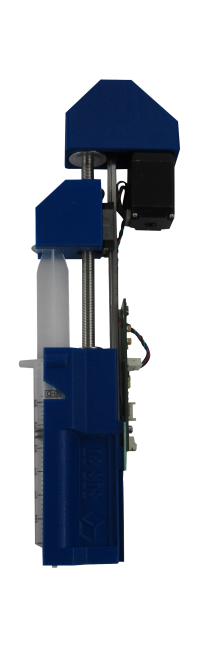

SDS

The SDS is our line of extruders for low viscosity emulsions which print at room temperature. The heads are available for 5, 10, 30, or 60cc plastic syringes.

This includes the following materials:

- Liquids

- Gels

- Emulsions

Videos

- Overview of the head:

- Loading SDS Heads:

Description

The SDS heads accept BD plastic syringe reservoirs in 5, 10, 30, or 60cc with luer fittings. Industry standard luer tips or needles are available from a variety of sources.

Syringes

Most SDS-type heads are designed for BD syringes. Custom designs for other syringes are possible, please contact us. For standard BD syringes, you may order them through us or from any reseller, but be sure to get the proper model number, as variations in form factor will cause the actual flow to vary from the calculated flow. Ardes syringes for the HSD-10 are heavily modified, so we recommend ordering these through us.

| Head | Syringe | Notes |

|---|---|---|

| SDS-01 | BD REF | Standard (one flange removed on early models) |

| SDS-05 | BD REF 309646 | Standard (one flange removed on early models) |

| SDS-10 | BD REF 309604 | Standard (one flange removed on early models) |

| HSD-10 Ardes | Ardes 011300 | Special Modifications |

| SDS-30, HSD-30, RSD-30 | BD REF 302832 | Standard (one flange removed on early models) |

| SDS-60, SDS-60XT | BD REF 309653 | Standard (one flange removed on early models) |

| SDS-150XT | BD REF | Standard |

Loading the Head onto the Printer

As with all Hyrel heads, the following process should be followed:

- Start with a level bed and Repetrel running and connected to the printer.

- Load the gibs on the Head into the gib slots on the Yoke from above and slide the head down into place; the last mm of travel should be done gently, ensuring that the electrical connector seats properly (firmly and completely) into the receiving connector.

- Ensure the LEDs on the print head are flashing - this means the Head is communicating with the Motion Controller.

- Tighten the thumbscrew in the rear, to prevent the head from moving relative to the Yoke.

- If the Head doesn't show up in Repetrel, press and release the RESET button on the front of the printer.

- Once the Head is shown in repetrel, proceed to setting your Z-Zero position.

Loading material into the Head

Loading:

- Care should be taken to avoid air pockets, as this will introduce delay when starting and stopping material flow.

- The plunger adapter will need to be adjusted up or down to match the position of the plunger for the amount of material you have loaded; do this with the manual feed lever at the top left of the 103 hothead controller board. See videos, above.

Unloading:

- Unloading is the same process as loading, only in reverse. Tubes and nozzles should be cleaned thoroughly after use.

Default Parameters

Default settings for all SDS series heads are shown on the Cold_and_Warm_Flow page.

Adjustments

The only adjustments needed should be changes to the PRIME and UNPRIME settings, and will have to be dialed in based on how viscous and compressible your material is, and how narrow a nozzle or luer tip you are using.. In dialing in new settings, I usually double or half the settings for both STEPS and TIME, then make another print and reassess.

Firmware

Please see the Downloads page for the current firmware for your heads and your version of Repetrel.

Note that the default version is _TUBES_35K.hex for standard use, or _TUBES_49V.hex with the Clench Valve.

Maintenance

With disposable syringes and luer tips to prevent cross-contamination, very little maintenance is required on these heads.